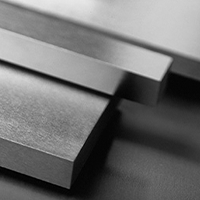

Precision Ground Flat Stock - Regular and oversized steel

Precision Ground Flat Stock (GFS) is a precision-ground flat bar made of alloyed or unalloyed steel and is also referred to as Gauge Stock or simply Flats.

The precision grinding ensures that all sides of the workpiece have a smooth surface and strictly controlled dimensional tolerances, and are free from surface defects and decarburization.

Additional designations for Precision Ground Flat Steel also include Key Stock, Shim Stock, Sheets, Strips, Squares, or Plates.

The precision grinding ensures that all sides of the workpiece have a smooth surface and strictly controlled dimensional tolerances, and are free from surface defects and decarburization.

Additional designations for Precision Ground Flat Steel also include Key Stock, Shim Stock, Sheets, Strips, Squares, or Plates.

Your success is our success!

Feel free to contact us.

WHAT IS PRECISION GROUND FLAT STOCK USED FOR?

Precision-ground flat stock steel is used in the manufacturing of precision tools for metalworking and is applied in many industries due to its exceptionally flat and precisely defined surface quality.

Here are some of the main areas of application:

• Toolmaking

• Mechanical Engineering

• Automotive Industry

• Electrical Industry

• Medical Engineering

• Aviation and aerospace

• Measurement and Control Technology

Here are some of the main areas of application:

• Toolmaking

• Mechanical Engineering

• Automotive Industry

• Electrical Industry

• Medical Engineering

• Aviation and aerospace

• Measurement and Control Technology

HOW IS PRECISION GROUND FLAT STOCK (PGFS) MADE?

To produce precision-ground flat steel, a piece of the needed material is cut to a specific length from a machined semi-finished material. Subsequently, the workpiece is surface ground to the required tolerances. Precise grinding of the surface ensures that there are no defects or carburization on the material.

• Raw Material Selection

• Rolling Process

• Heat Treatment

• Precision Grinding

• Surface Grinding

• Quality Control

• Raw Material Selection

• Rolling Process

• Heat Treatment

• Precision Grinding

• Surface Grinding

• Quality Control

DIFFERENCE BETWEEN PRECISION GROUND FLAT STEEL AND FLAT BAR

Precision ground flat steel and conventional flat steel primarily differ in their surface finish and tolerances.

As a Regular and Oversize Ground Flat Stock Steel Supplier for Imperial and Metric Steel Sizes, we not only provide standard stock products but also offer solutions tailored specifically to your needs, to serve the technical and commercial requirements of our customers.

Regular and Oversize Ground Flat Steel is often subjected to extremely high stresses, and no single steel offers features such as maximum wear resistance, hardness, and toughness. Our steel portfolio includes the most common steel dimensions and steel grades, to offer an optimal combination of properties and desired size for a specific application.

It can be very frustrating to search for the optimal imperial and metric Ground Flat Stock Steel grade for all your applications. We’ve got the perfect solution for this.