5120 Tool Steel - ~1.2162 / 1.7147 - ~21MnCr5 / 20MnCr5

5120 Tool Steel - ~1.2162 / 1.7147 - ~21MnCr5 / 20MnCr5

Back to Steel Overview

5120 STEEL PRICE CHART

5120 STANDARD VALUES

C

Si

Mn

P

S

Cr

~21MnCr5 / 20MnCr5

58 HRC - 60 HRC

max. 217 HB

~21MnCr5 / 20MnCr5

58 HRC - 60 HRC

max. 217 HB

5120 PHYSICAL PROPERTIES

The 5120 is a case hardening steel with high strength, good toughness, hardenability and machinability.

After case hardening this tool steel grade it has a tough core and a hard shell which makes it useful for a wide variety of applications like nuts and bolts, spindles and camshafts and pinions and shafts.

5120 TECHNICAL PROPERTIES

As the 5120 is not corrosion resistant it has to undergo thorough maintenance like regular cleaning, keeping it dry and maybe oiling the blade to prevent it from rusting. With that in mind the 5120 can be used for outdoor knives, cutlery knives or general purpose knives.

Typically the density of tool steel 5120 is 0.284 lb/in3 (7.85g/cm3) at room temperature.

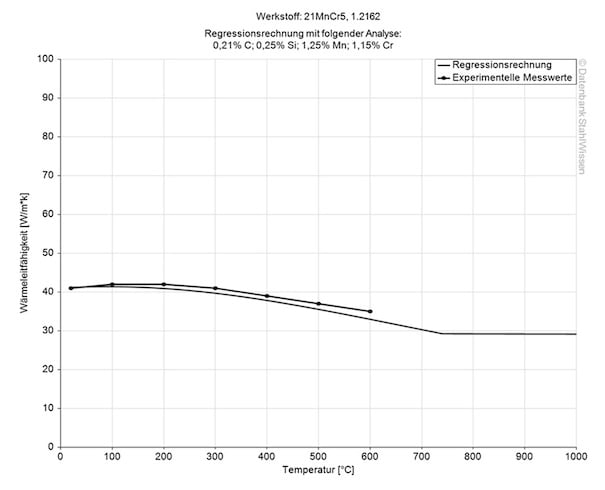

The thermal conductivity for tool steel 5120 is at 39.5 W/(m*K) (274 BTU/(h-ft*°F)) at room temperature.

Heat conductivity table | |

Value | By temperature |

39.5 | 68°F |

36.5 | 662°F |

33.5 | 1292°F |

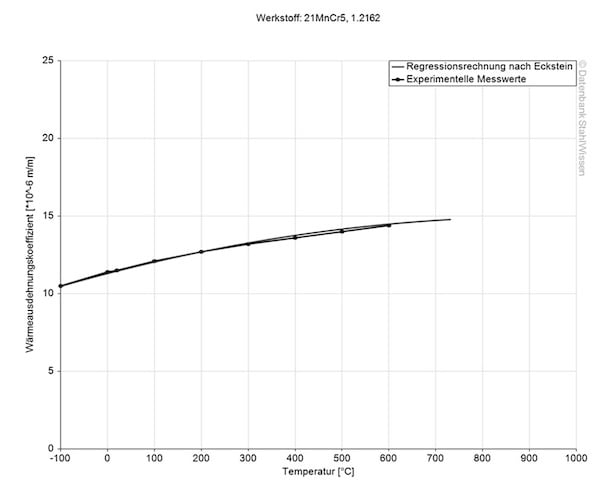

Medium thermal expansion coefficient | |

10-6m/(m • K) | At a temperature of |

12.2 | 68 - 212°F |

12.9 | 68 - 392°F |

13.5 | 68 - 572°F |

13.9 | 68 - 752°F |

14.2 | 68 - 932°F |

14.5 | 68 - 1112°F |

14.8 | 68 - 1292°F |

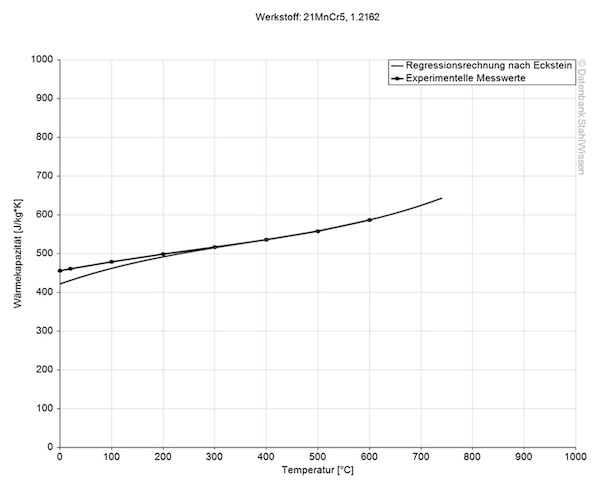

The specific heat capacity for this steel grade is 0.475J/g-°C (0.113 BTU/lb-°F).

This value shows how much heat is needed to heat 1lb of material by 1 Fahrenheit.

Table of the specific electrical resistivity | |

Value | At a temperature of |

0.16 (Ohm*mm²)/m | 68°F |

STEEL MADE WITH ”STYLE“ !

5120 PROCEDURE

This process can reduce the hardness of the steel or increase the toughness of it as well as relieve internal stresses.

This process is done to refine grain structure as well as to improve the materials toughness, strength and machinability.

Quenching the 5120 quickly after carburizing will lock the added carbons into the surface.

• Oil

• Water (for simple shaped large components)

• Salt bath

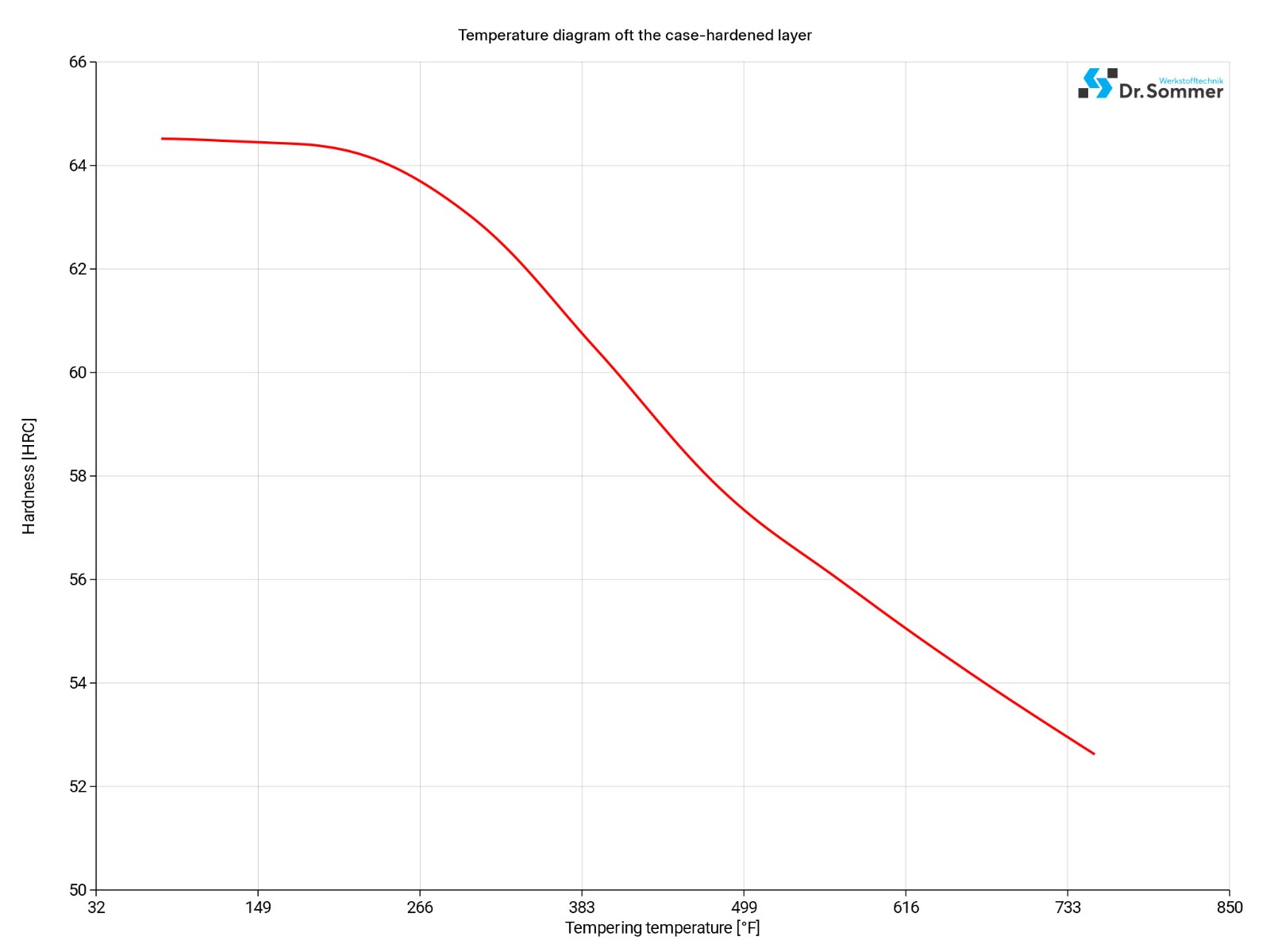

Temper parts 1 hour per 25/32 inch (20 mm) thickness but a minimum of 2 hours at a temperature of 338 - 410°F (170 - 210°C).

Tempering can relieve internal stresses that have been introduced during quenching the 5120.

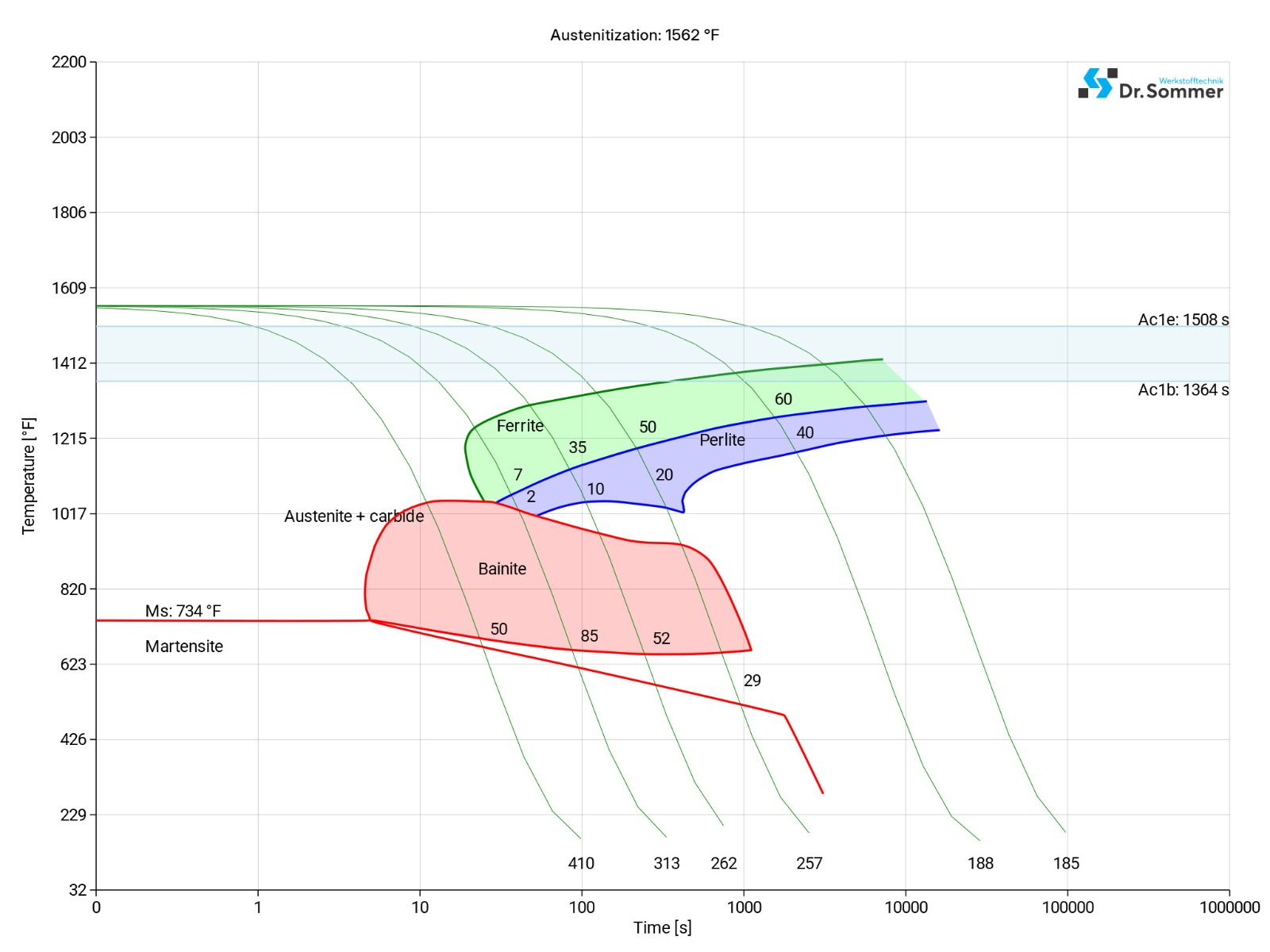

This diagram shows micro changes over time at different temperatures. Those are important during heat treatment as they show information about the optimum conditions for processes such as hardening, annealing and normalizing.

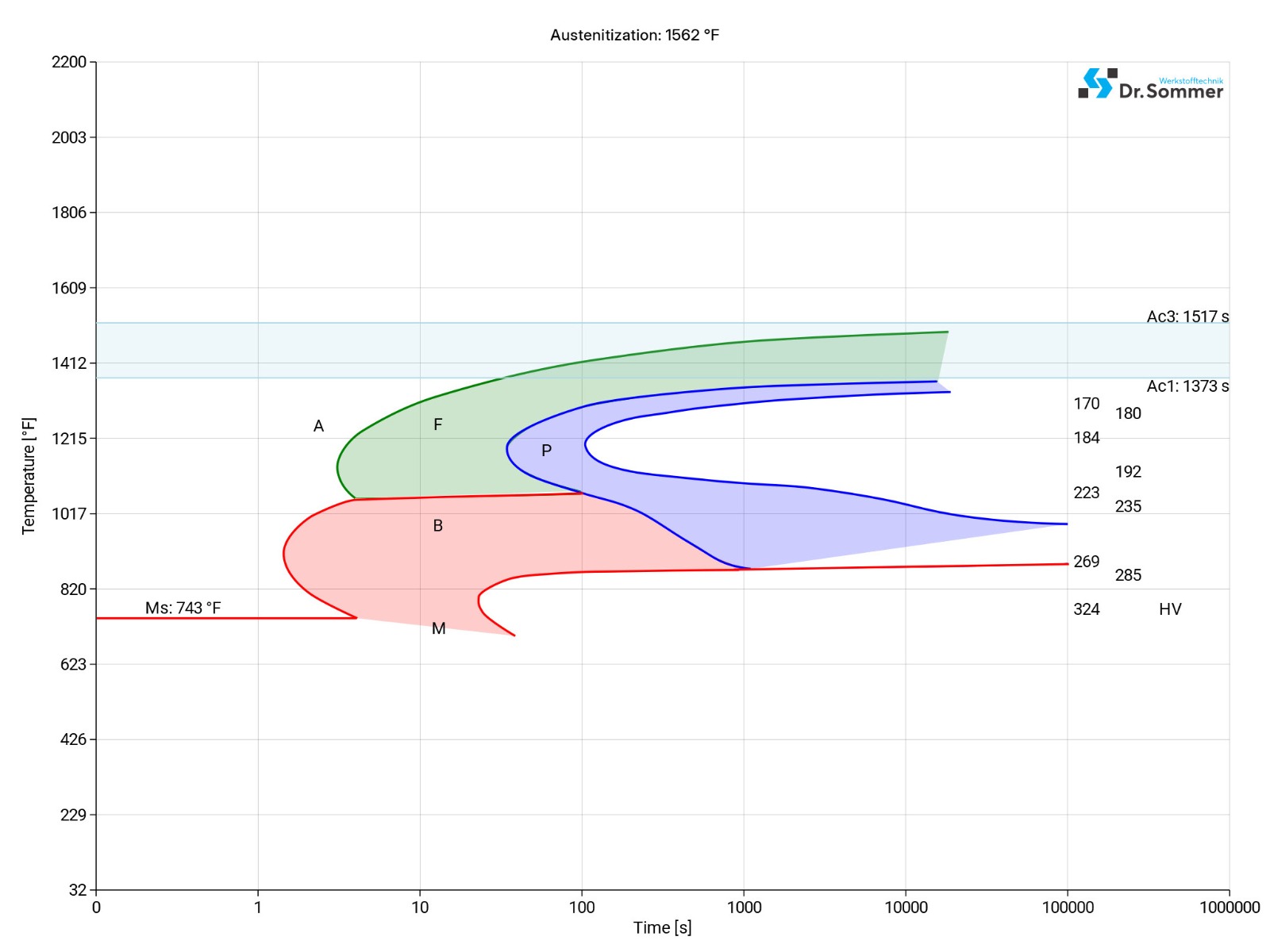

This diagram shows the structural changes at micro level over time at a constant temperature. It shows at what temperature and after what time different phases, e.g., perlite, martensite or bainite start to build.

5120 SURFACE TREATMENT

Heat the material to a temperature range of 1652 - 1742°F (900 - 950°C). With intended process and required microstructure in mind choosing the right temperature, time, medium and equipment is important.

Carburizing introduces carbon into the surface of the material to give it a harder shell and to retain a tough core, this will give the material the ability to withstand wear and at the same time being tough enough to withstand high impact.

5120 PROCESSING

On a scale where 1 is weak and 6 is good, the machinability of 5120 reaches a score of 5.

5120 should be machined in its normalized condition and before it is case hardened.

EDM is used for parts made from one individual piece, for cutting dies or when making intricate shapes. There are various methods to erode various materials, some of them are for example wire erosion, spark erosion or die sink erosion.

The 5120 has limited weldability. Welding should be done before the heat treatment. Preheat the part to 482 - 662°F (250 - 350°C), post heat treatment is based on the heat treatment of the base material.

5120 APPLICATION OPTIONS

5120 is a case hardening steel, which is often used for medium to highly stressed parts, for example gears, gear shafts and connecting rods, in the automotive and general engineering industry.

It also finds its uses as mold plates due to its surface hardness or resin press molds to process thermoplastics as well as gauges, other measuring tools and auxiliary tools such as clamping tools. This case hardening mold steel can reach a core strength of approx. 145-189 KSI (1000 - 1300 MPa).

• Mechanical engineering

• Jig construction

• Plant engineering

• Apparatus engineering

• Plastic processing

• Plastic molds

• Synthetic resin mold tools

• Base plates

• Bending bars

• Guide columns

• Gear parts

• Joint parts

• Shafts

• Gears

• Rods

• Bevel gears

• Crown wheels

• Piston pins

• Camshafts

• Bolts

• Pins

• Cardan joints

5120 CONCLUSION

5120 has a good combination of strength, hardness and toughness. Due to those properties it is a great choice for applications with high stress and for applications that need good wear resistance. To give this tool steel even better wear resistance and/or enhance its corrosion resistance it can be surface treated to enhance tool service life. This steel grade can be hardened through or case hardened which can both be useful for several different applications.

- Cold work steel

- Plastic mold steel

- Wear-resistant surface

- Tough core

- Very good machinability

- Good cold sinkability

- Good polishability

- Component tensile strength results from the combination of hardened surface layer and tough core

We offer this steel as Metric 5120 Precision Ground Flat Stock and 5120 Flat Stock.

5120 ALTERNATIVES

Are you looking for an alternative steel grade?

WE HAVE THE SOLUTION!

With the ABRAMS STEEL GUIDE, you can obtain an alternative or equivalent steel grade with just a few clicks.

5120 DATASHEET

Download the technical data sheet in PDF format here.

The data shown here has been compiled with the greatest diligence and is regularly updated with regard to the correctness and completeness of its content. The content is indicative only and should not be taken as a warranty of specific properties of the product described or a warranty of suitability for a particular purpose. All information presented is given in good faith and no liability will be accepted for actions taken by third parties in reliance on this information. ABRAMS Industries reserves the right to change or amend the information given here in full or parts without prior notice.