S1 Tool Steel - DIN 1.2550 - 60WCrV8 - Chromium and tungsten

S1 Tool Steel - DIN 1.2550 - 60WCrV8 - Chromium and tungsten

Back to Steel Overview

S1 STEEL PRICE CHART

S1 STANDARD VALUES

C

Si

Mn

P

S

Cr

V

W

60WCrV8

56 HRC - 60 HRC

max. 229 HB

60WCrV8

56 HRC - 60 HRC

max. 229 HB

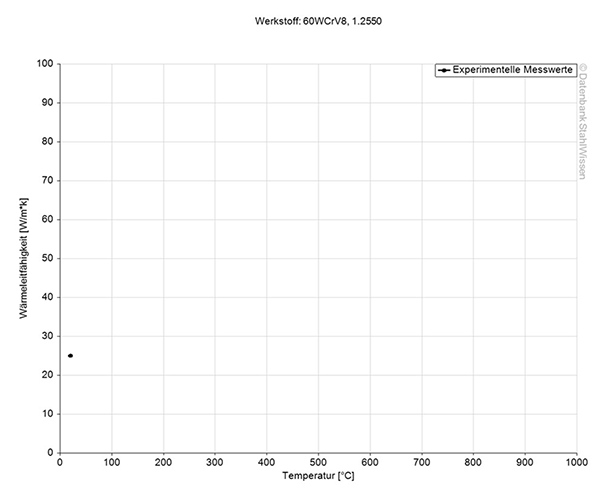

S1 PHYSICAL PROPERTIES

The added chromium and tungsten in tool steel S1 give this steel grade its excellent dimensional stability. In addition the added tungsten gives the S1 its toughness and wear resistance.

The added silicon in this steel grade forms a microstructure which can resist distortion in the tempered condition. These added alloys make the S1 a reliable choice for tools which have to withstand high stresses and for the use in cold work.

To be classed as a stainless steel the steel has to have a mass fraction of 10.5% chromium.

S1 can corrode when exposed to moisture, chemicals and corrosive environments. Regular maintenance and dry storage of tools will help prolong the tools live. Oiling or otherwise coating the material with a protective layer might safeguard against moisture or corrosive environments.

Forming, cutting and shaping the S1 like for application as blanking dies, punches, cold forming dies or shear blades can be done at temperatures close to room temperature.

S1 TECHNICAL PROPERTIES

Typically the density of tool steel S1 is 0.285 lb/in3 (7.89 g/cm3) at room temperature.

The yield strength shows how much stress has to be applied to plastically deform and when the point is reached for the material not to return to its original state after stresses have been removed. It then either stays in the mischaped form or breaks.

The thermalt conductivity for tool steel S1 is 34.2 W/(m*K) (237 BTU/(h-ft*°F)) at room temperature.

Heat conductivity table | |

Value | By temperature |

34.2 | 68°F |

32.6 | 662°F |

30.9 | 1292°F |

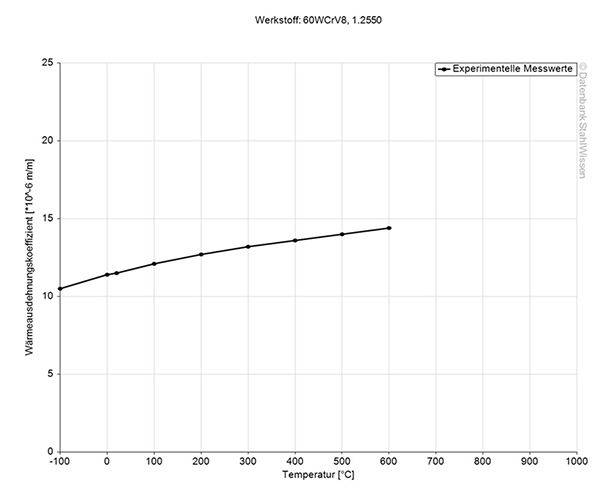

Medium thermal expansion coefficient | |

10-6m/(m • K) | At a temperature of |

11.8 | 68 - 212°F |

12.7 | 68 - 392°F |

13.1 | 68 - 572°F |

13.5 | 68 - 752°F |

14.0 | 68 - 932°F |

14.3 | 68 - 1112°F |

14.5 | 68 - 1292°F |

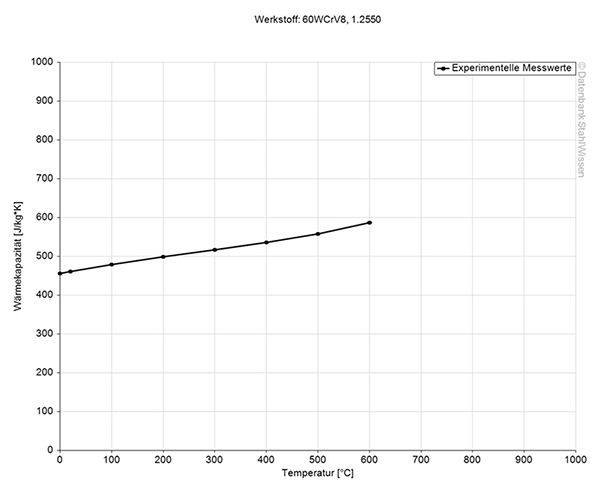

The specific heat capacity for the S1 tool steel at room temperature is 0.46 J/g-°C (0.109 BTU/lb-°F). This value shows how much heat is needed to heat 1lb of material by 1 Fahrenheit.

Table of the specific electrical resistivity | |

Value | At a temperature of |

0.3 (Ohm*mm²)/m | 68°F |

70 STEEL GRADES IN THOUSANDS STANDARD DIMENSIONS AVAILABLE FROM STOCK!

S1 PROCEDURE

Uniformly and slowly heat the work pieces through to 1202°F (650°C) after rough machining for example. Hold and then slowly cool in still air. Then finish machining the parts.

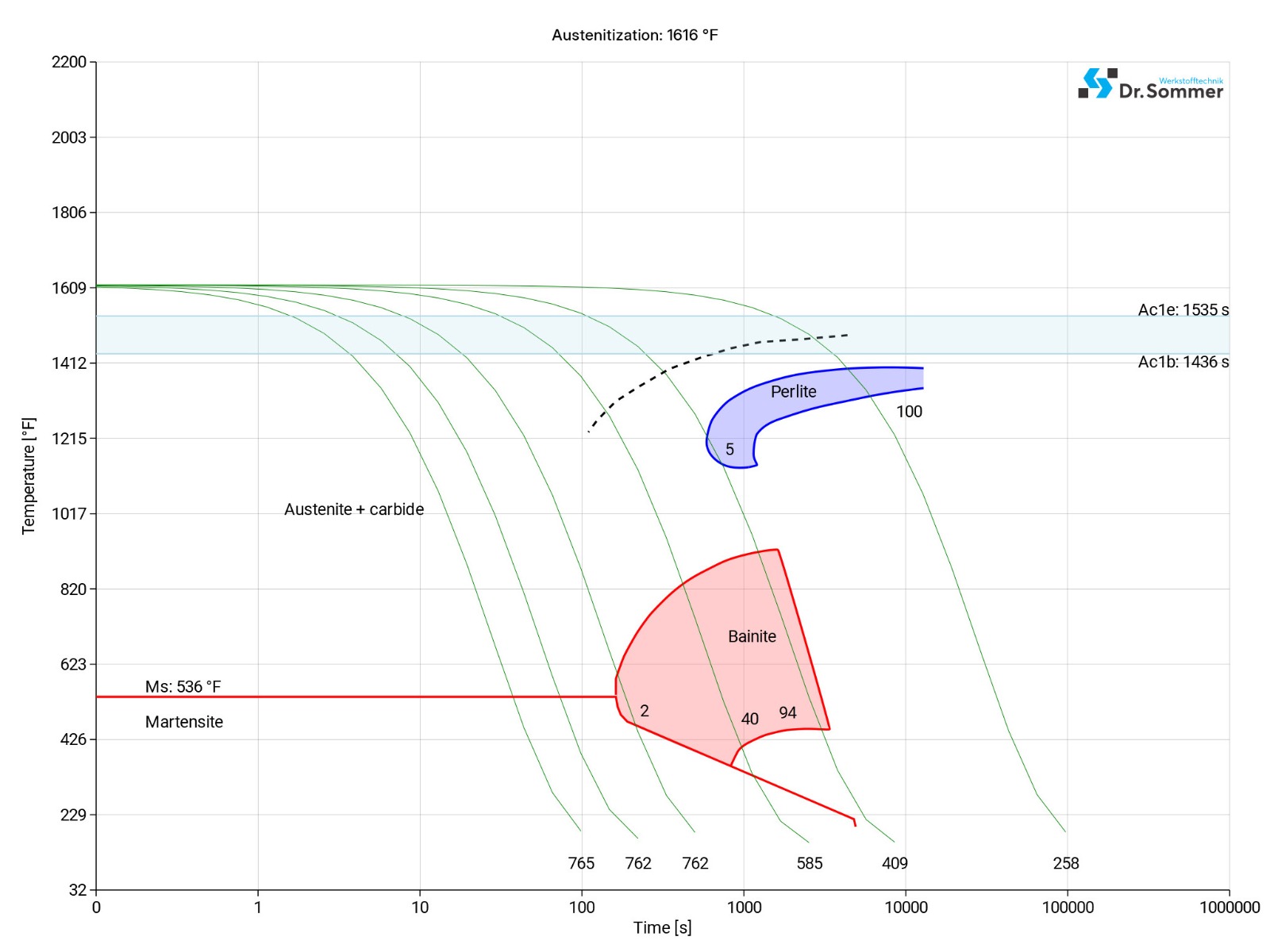

Commonly the quenching media for the S1 tool steel are:

• Oil

• Salt bath 356 - 428°F (180 - 220°C)

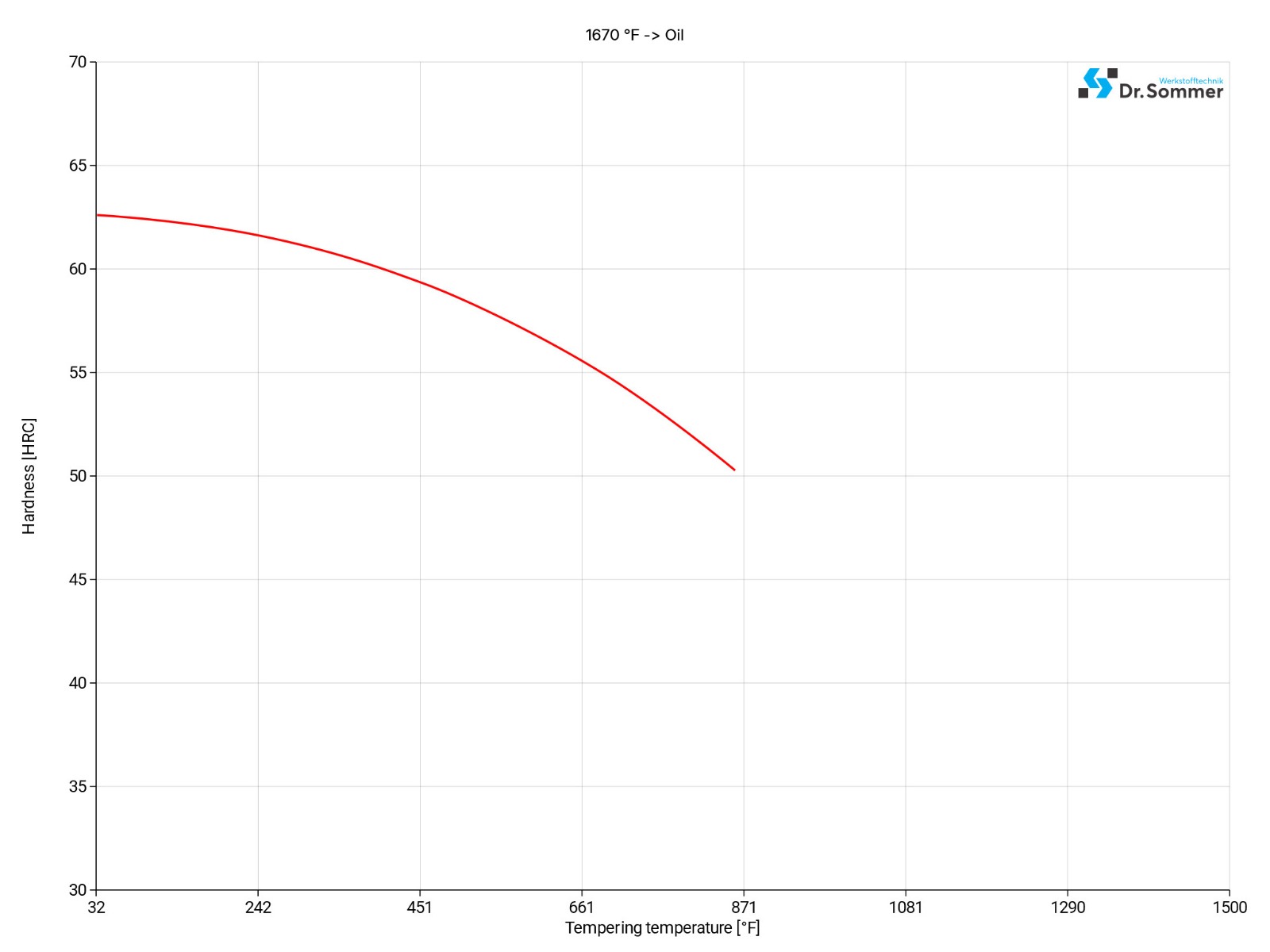

After quenching the S1 is extremely hard and brittle, to reduce this and to improve toughness the steel should be tempered.

Slowly heat the S1 tool steel parts to the required tempering temperature and soak the material for 1 hours per inch (25.4 mm) thickness and follow with cooling the parts down in air.

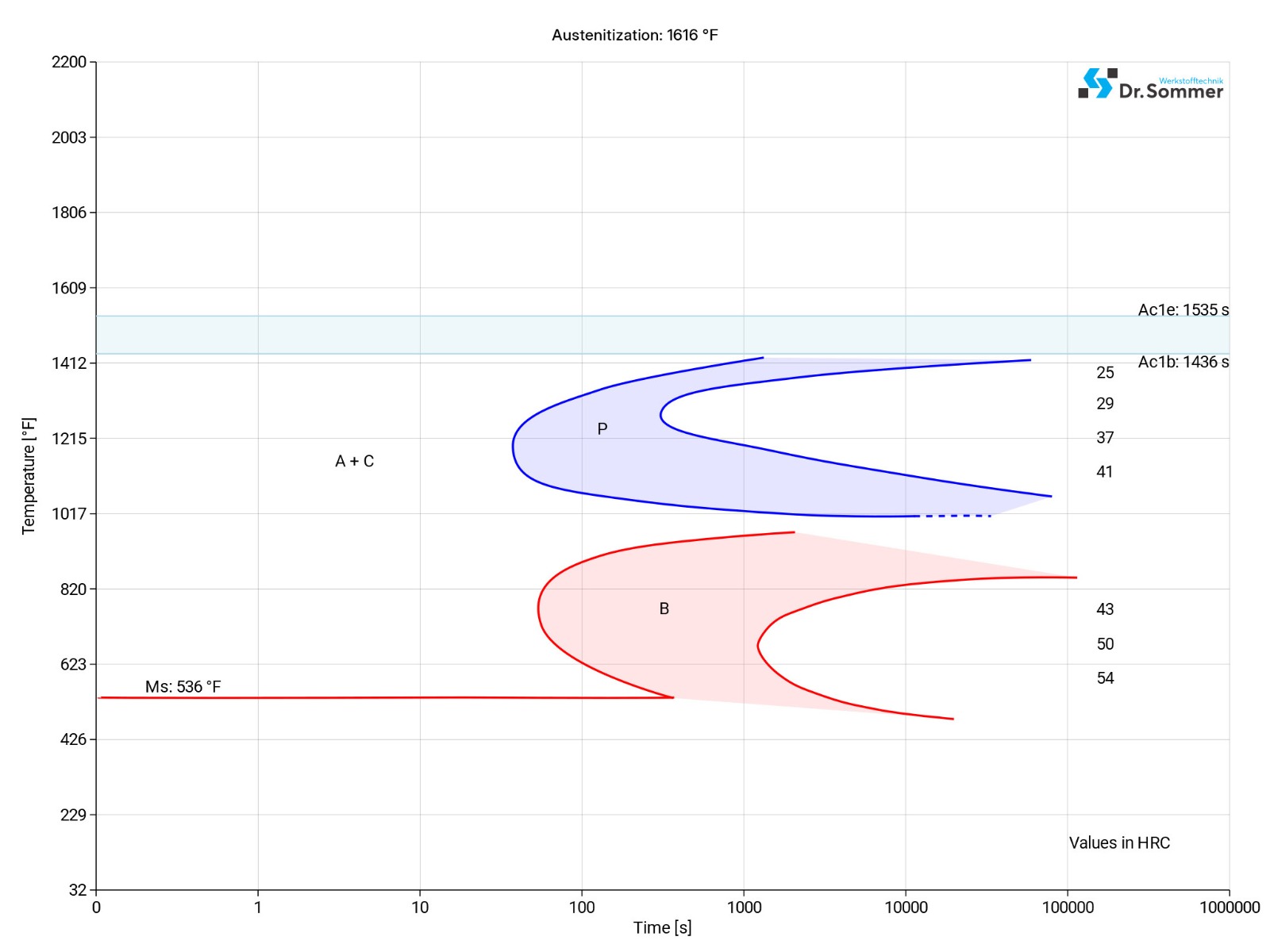

For more information, please look at the S1 annealing chart below.

This diagram shows the micro changes at different temperatures which are important during heat treatment. They show the optimum condition for the hardening, annealing and normalizing process.

This diagram shows the structural changes at micro level over time at a constant temperature. It shows at what temperature and after what time different phases, e.g., perlite, martensite or bainite start to build.

S1 SURFACE TREATMENT

As the S1 is not a stainless steel, passivation has some advantages for certain applications.

S1 PROCESSING

On a scale where 1 is weak and 6 is good, the machinability of S1 reaches a score of 4.

Depending on hardness, cutting speed, feed rates, lubrication, heat treatment, choice of cutting tools as well as tool life the S1 is fairly good to machine.

Stress relieving the S1 may cause dimensional changes, as well as putting high mechanical loads on to the material. Heavy loads may result in elastic or plastic deformation and may lead to failure or changes to the shape and dimensions.

Reheat as often as needed and avoid forging under 1472°F (800°C). To prevent stress to the material, cool it slowly in the furnace after forging.

Ensuring the base metal is clean from contamination such as grease, rust, oil, and moisture, remove sharp edges and make sure to check for surface cracks before welding.

When choosing filler metals, the tensile strength and yield strength of the base metal should be taken in consideration and either matched to the base metal or should be stronger than the base metal.

S1 APPLICATION OPTIONS

As a high impact and shock resistant tool steel the S1 is suitable for applications exposed to severe mechanical stresses.

• Blanking tools

• Dies

• Punches

• Forming dies

• Embossing tools

• Coining tools

• Tableting punches

• Plug-in tools

• Trimming tools

• Cold shear knives

• Riveting pins

• Hand chisels

• Pneumatic chisels

• Centre punches

• Ejectors

• Woodworking tools

S1 CONCLUSION

Practically, this means:

- Impact resistant

- Robust

- Good wear resistance

- Good heat resistance

- Can be nitrided

- Not corrosion resistant

- Difficult to machine in hardened condition

- Certain properties can only be achieved with a precise heat treatment process

- Working hardness is 56 - 60 HRC

We offer this steel as S1 Flat Stock.

S1 ALTERNATIVES

Are you looking for an alternative steel grade?

WE HAVE THE SOLUTION!

With the ABRAMS STEEL GUIDE, you can obtain an alternative or equivalent steel grade with just a few clicks.

S1 DATASHEET

Download the technical data sheet in PDF format here.

The data shown here has been compiled with the greatest diligence and is regularly updated with regard to the correctness and completeness of its content. The content is indicative only and should not be taken as a warranty of specific properties of the product described or a warranty of suitability for a particular purpose. All information presented is given in good faith and no liability will be accepted for actions taken by third parties in reliance on this information. ABRAMS Industries reserves the right to change or amend the information given here in full or parts without prior notice.