52100 / L1 Tool Steel - 1.3505 - 100Cr6 - JIS ~SUJ 2

52100 / L1 Tool Steel - 1.3505 - 100Cr6 - JIS ~SUJ 2

Back to Steel Overview

52100 / L1 STEEL PRICE CHART

52100 / L1 STANDARD VALUES

C

Si

Mn

P

S

Cr

Mo

Ni

100Cr6

60 HRC - 64 HRC

max. 223HB

100Cr6

60 HRC - 64 HRC

max. 223 HB

52100 / L1 PHYSICAL PROPERTIES

52100 tool steel, also known as L1, is a cold work, high carbon chromium steel that is used for rolling bearings as well as tools. 52100 is a classic ball bearing steel, often used for needle bearings, ball bearings as well as for components that are exposed to wear, like pump shafts.

Due to its wear properties this steel grade is often also used for pump shafts and injection systems in engines, for this it is often surface hardened.

Ball bearing manufacturers use this steel for its high hardness capability, excellent wear- and deformation resistance. To fulfill the requirements of the bearing industry to ASTM A295, the sulphur content is reduced to 0.015% and it is vacuum-induction-melted, followed by a vacuum-arc-remelt for a cleaner steel with a more uniform microstructure.

At a temperature of less than 400°F (200°C), 52100 retains its good rolling fatigue strength.

The composition of high carbon and chromium give this steel unique properties which makes it suitable for ball and roller bearings. It stands out with its high hardness, high fatigue strength and good stability.

A classic stainless steel contains a mass fraction of at least 10.5% chromium, 52100 has a mass fraction of chromium of 1.4 - 1.6% and is therefore not a stainless steel.

With its low chromium content it has not the corrosion resistance like stainless steels and should be coated with a protective layer when used in corrosive environments.

The 52100 steel composition of high carbon and low chrome does not give this steel grade the protective oxide layer to protect it. It therefore is at a high risk of corroding when exposed for a longer time to moisture, saltwater or other corrosive agents. Maintenance and an added protective layer should be applied to protect parts to give them a longer service life.

With its low chromium content it has not the corrosion resistance like stainless steels and should be coated with a protective layer when used in corrosive environments.

The 52100 steel composition of high carbon and low chrome does not give this steel grade the protective oxide layer to protect it. It therefore is at a high risk of corroding when exposed for a longer time to moisture, saltwater or other corrosive agents. Maintenance and an added protective layer should be applied to protect parts to give them a longer service life.

52100 carbon steel can suffer oxidation when exposed to high temperatures over a long time or when exposed to an environment containing a high amount of oxygen or gasses.

52100 alloy steel is susceptible to corrosion cracking in specific environments but can also be influenced by the heat treatment or what stresses parts are under too.

The iron in the 52100 tool steel gives this grade its ferromagnetic properties which makes this material magnetic.

The wear resistance for the 52100 steel is at 4 on a scale where 1 is low and 6 is high.

This material can be hot worked at a temperature range of 400-1000°F (205-538°C).

51200 steel can be cold worked in its annealed or normalized condition using conventional techniques.

52100 / L1 TECHNICAL PROPERTIES

52100 is not only a bearing steel but also popular as a knife steel for e.g., hunting knives. It has a good edge retention and can be sharpened well. As the corrosion resistance for this steel grade is not high, knife blades should be kept dry, dust free and oiled.

The working hardness for the 52100 is at 627 - 659 BHN (60 - 64 HRC).

Typically the density of the 52100 is 0.282 lb/in3 (7.81 g/cc) at room temperature.

The tensile strength for 52100 is approx. 108,7 KSI (0.145KSI = 1MPa) on delivery. This value is the result from a tensile test to show how much force is needed before the material starts to stretch or elongate before it breaks.

The yield strength shows how much stress needs to be applied before the material starts to deform and does not regain the original form.

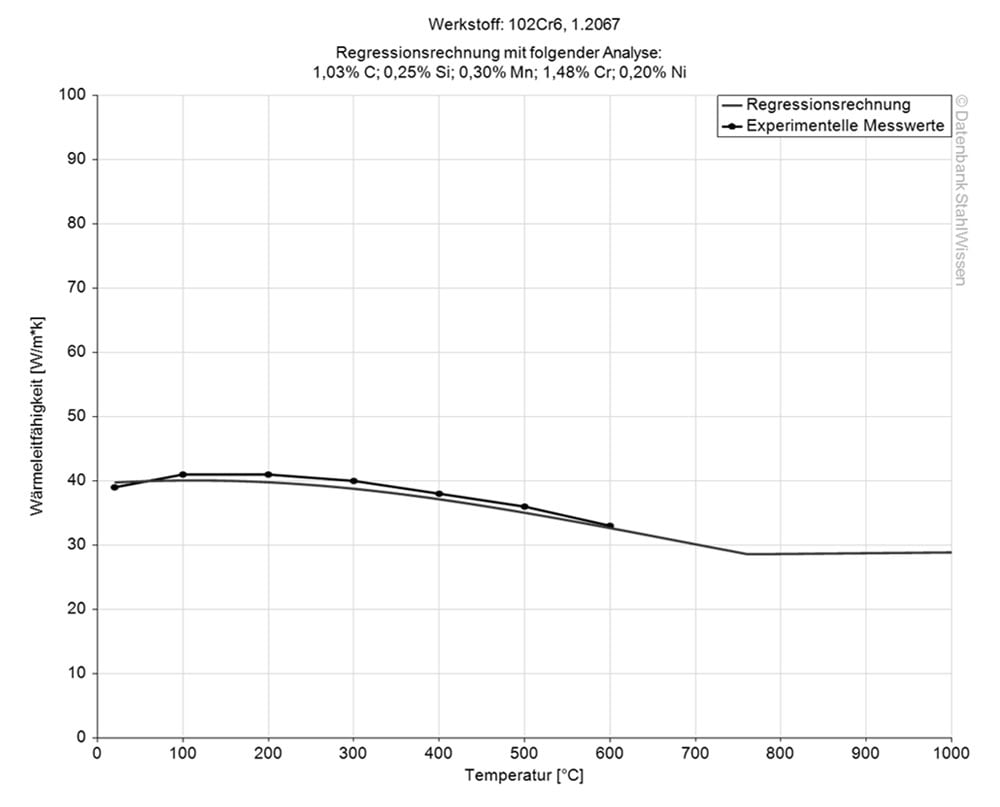

The heat conductivity for 52100 is at 46,6 W/(m*K) (323 BTU/(h-ft*°F)) at room temperature.

Heat conductivity table | |

Value | By temperature |

33.0 | 68°F |

32.2 | 662°F |

31.4 | 1292°F |

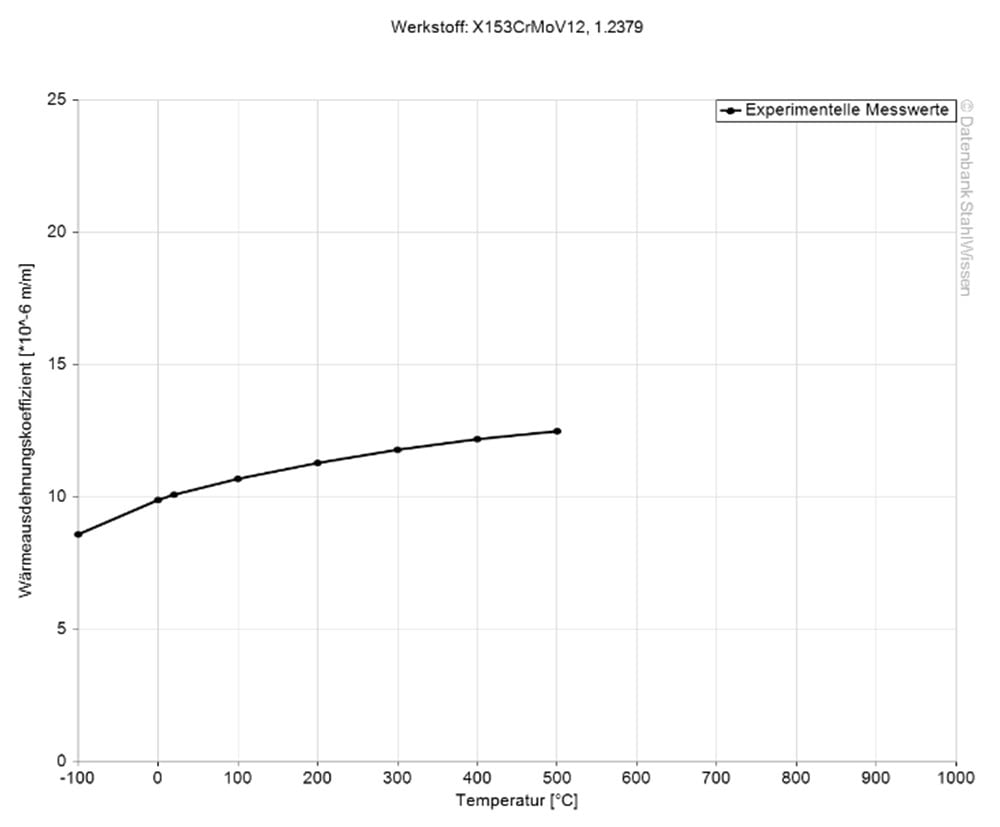

The 52100 thermal expansion coefficient shows how much the material might expand or contract when the temperature is changed.

This is very important information, especially when working with high temperatures, or where there are strong temperature changes during applications.

The thermal expansion coefficient is typically in the region of approx. 12.3 in/(in*F) at room temperature.Medium thermal expansion coefficient | |

10-6m/(m • K) | At a temperature of |

12.3 | 68 - 212°F |

13.4 | 68 - 392°F |

13.7 | 68 - 572°F |

14.1 | 68 - 752°F |

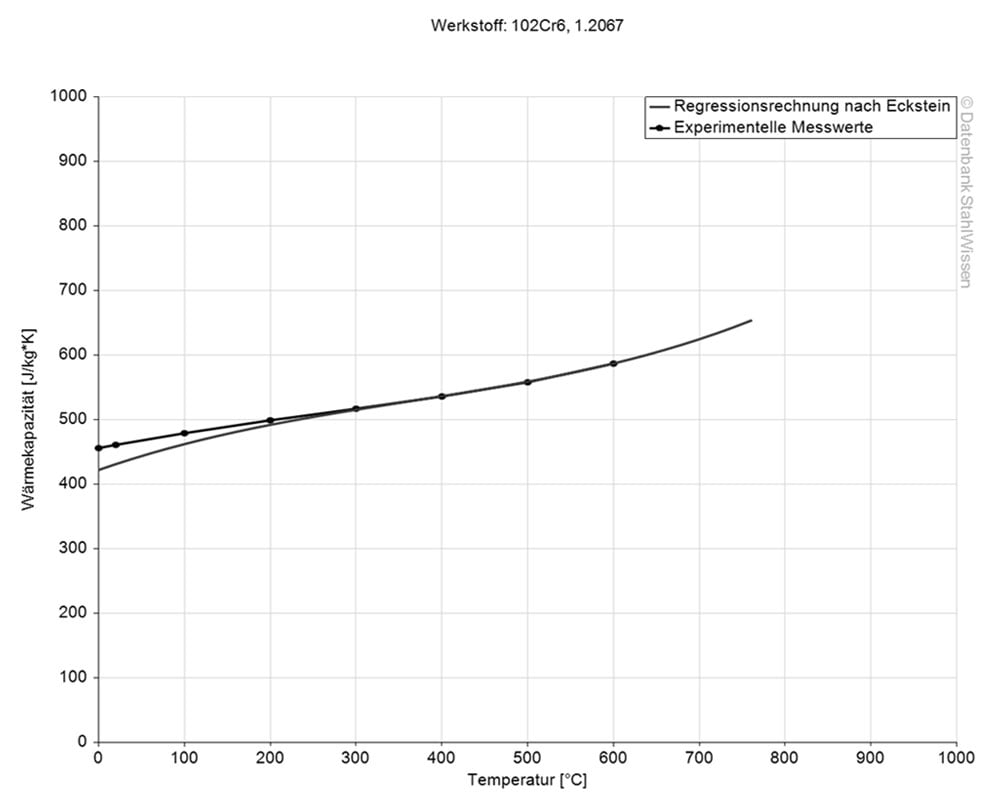

The specific heat capacity of 52100 at room temperature is at approx. 0.475 J/g-°C (0.114 BTU/lb-°F). This value shows how much heat is needed to heat 1lb of material by 1 Fahrenheit.

ORDER THE SMALLEST AMOUNT - WITHOUT A MINIMUM ORDER VALUE!

52100 / L1 PROCEDURE

Heat the workpiece uniformly to a temperature of 1440°F (782°C) and soak for two hours. Slowly cool to a temperature of 1200°F (649°C) at 25°F (10°C) per hour and further cool to an ambient temperature in the furnace or air.

The slow cooling builds a ferritic pearlitic formation, this structure affects the softness of this grade and makes it more machinable. To prevent decarburization or oxidation 52100 should be annealed under controlled conditions or protected by a stainless steel wrap.

Stress relieving 51200 is done at a temperature of 1200°F (649°C) with a slow cooling to room temperature. 52100 has to be cooled down slowly so as not to develop residual stresses or change the microstructure.

Further, if 52100 has been hardened, the temperature used to relieve internal stresses should not exceed the tempering temperature as the material can soften.

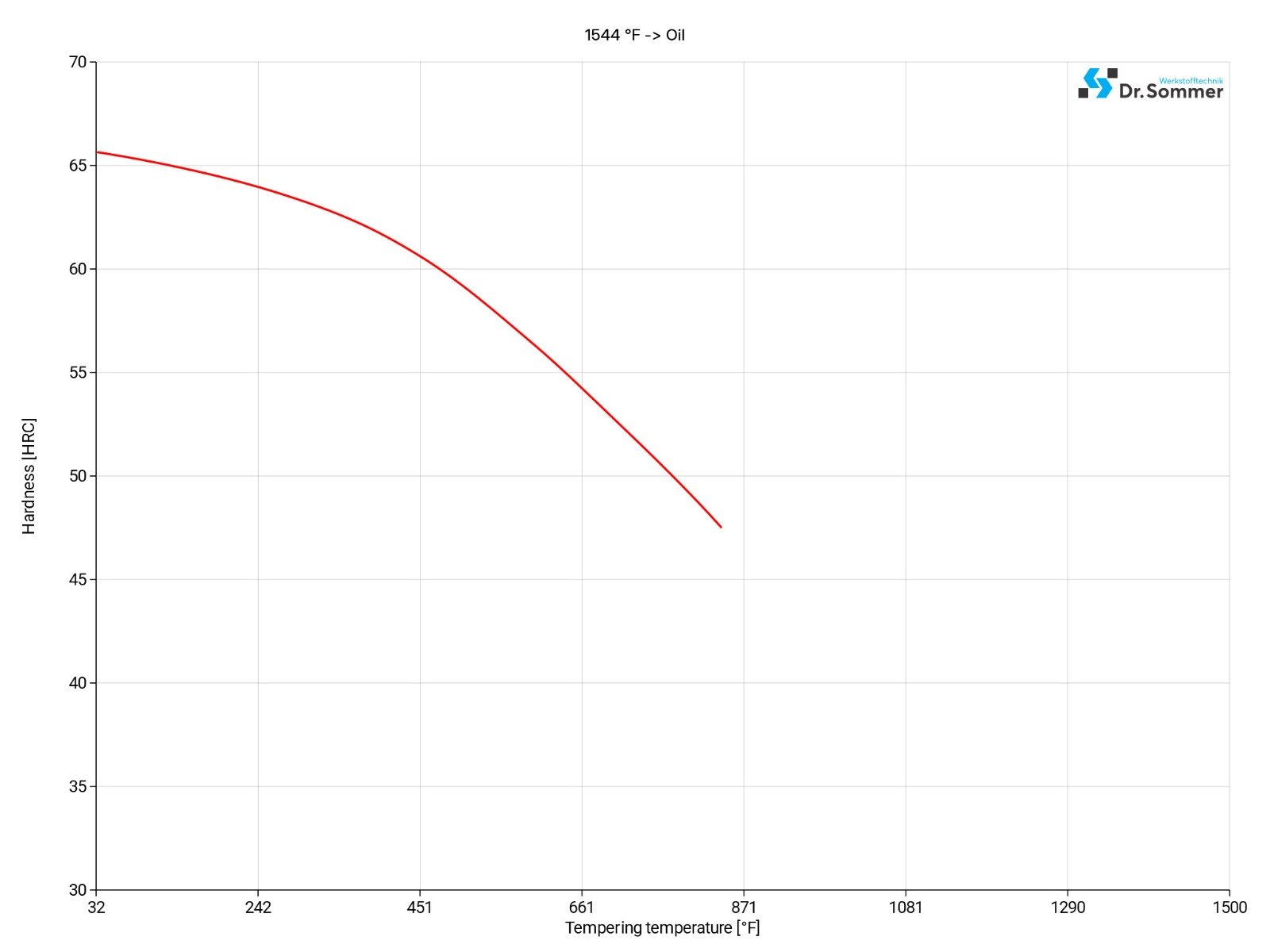

Hardening will give the 52100 steel mechanical properties needed when used in bearing applications. Heat the material slowly to a temperature of 1500-1550°F (816-843°C) and soak for about 10-30 minutes.

To vacuum or oil harden this material, use the higher temperatures mentioned here as well as the longer soaking time. Workpieces with a thickness up to 1 inch (25.4 mm) should be quenched in oil, parts under 1 inch should be quenched in water.

After the workpieces are quenched, they are cooled down to an ambient temperature and tempered immediately.

52100 steel hardness is between 627 - 745 BHN (60 - 68 HRC).

Most common media to quench 52100 in are the following:

• Water

• Oil

Heat the parts uniformly to a temperature of 1700°F (927°C) and cool in still air after. This step can prepare the material for machining or further heat treatment and will give the 52100 a refined grain structure.

Care should be taken though to avoid or minimize decarburization and oxidation. As for annealing this material, normalizing should be done in a protective environment or it should be protected with a stainless steel wrap.

Heat the parts to a temperature range of 300-500°F (149-260°C) and hold for at least 2 hours, then air cool to an ambient temperature.

52100 has multiple benefits when treated at sub-zero temperatures.

As this treatment converts remaining austenite to martensite, 52100 benefits with a refined structure, which in turn can benefit the dimensional stability. This treatment can enhance the wear resistance which is needed when using 52100 as a steel ball for bearings.

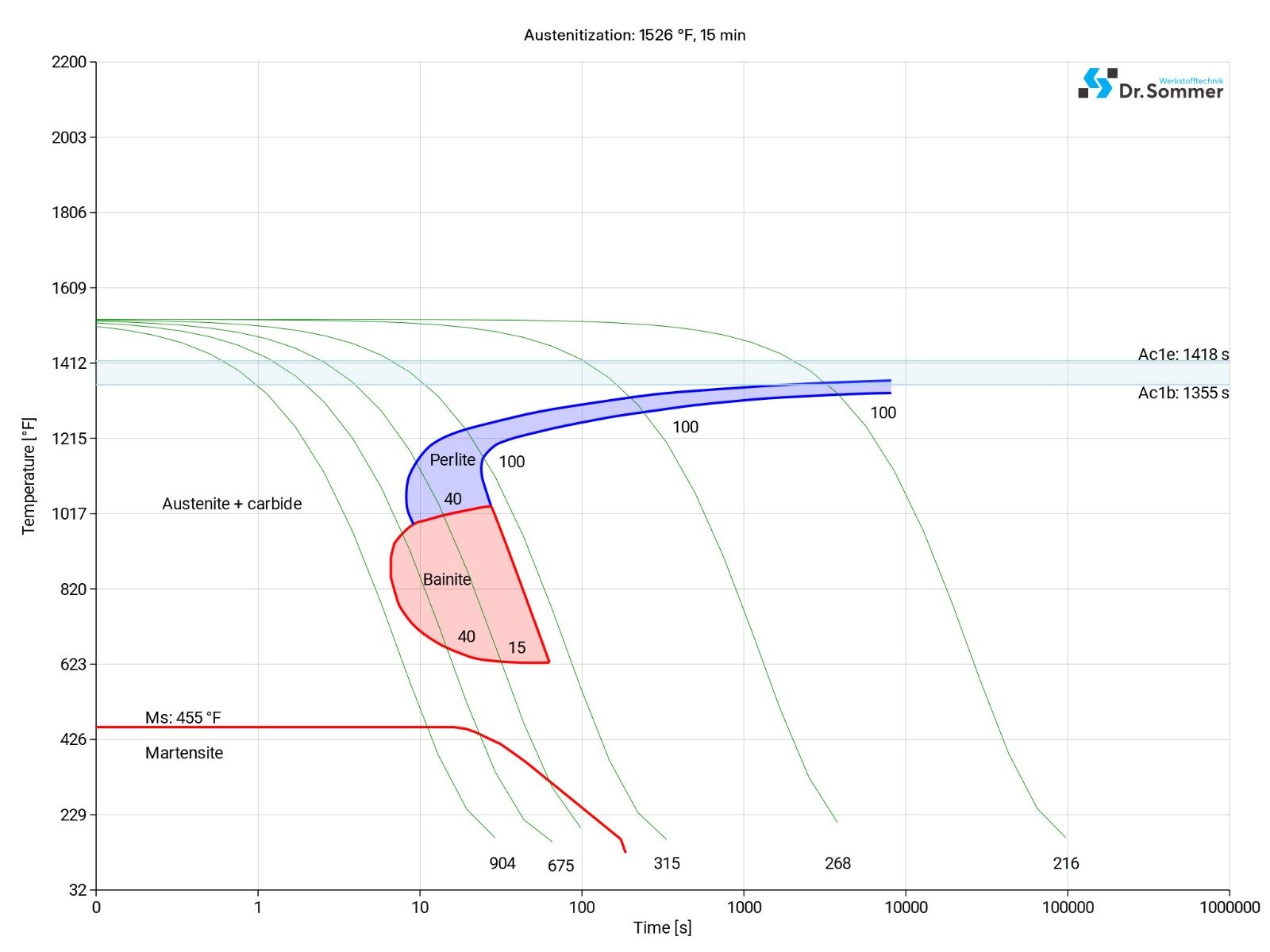

This diagram shows micro changes over time at different temperatures. Those are important during heat treatment as they show information about the optimum conditions for processes such as hardening, annealing and normalizing.

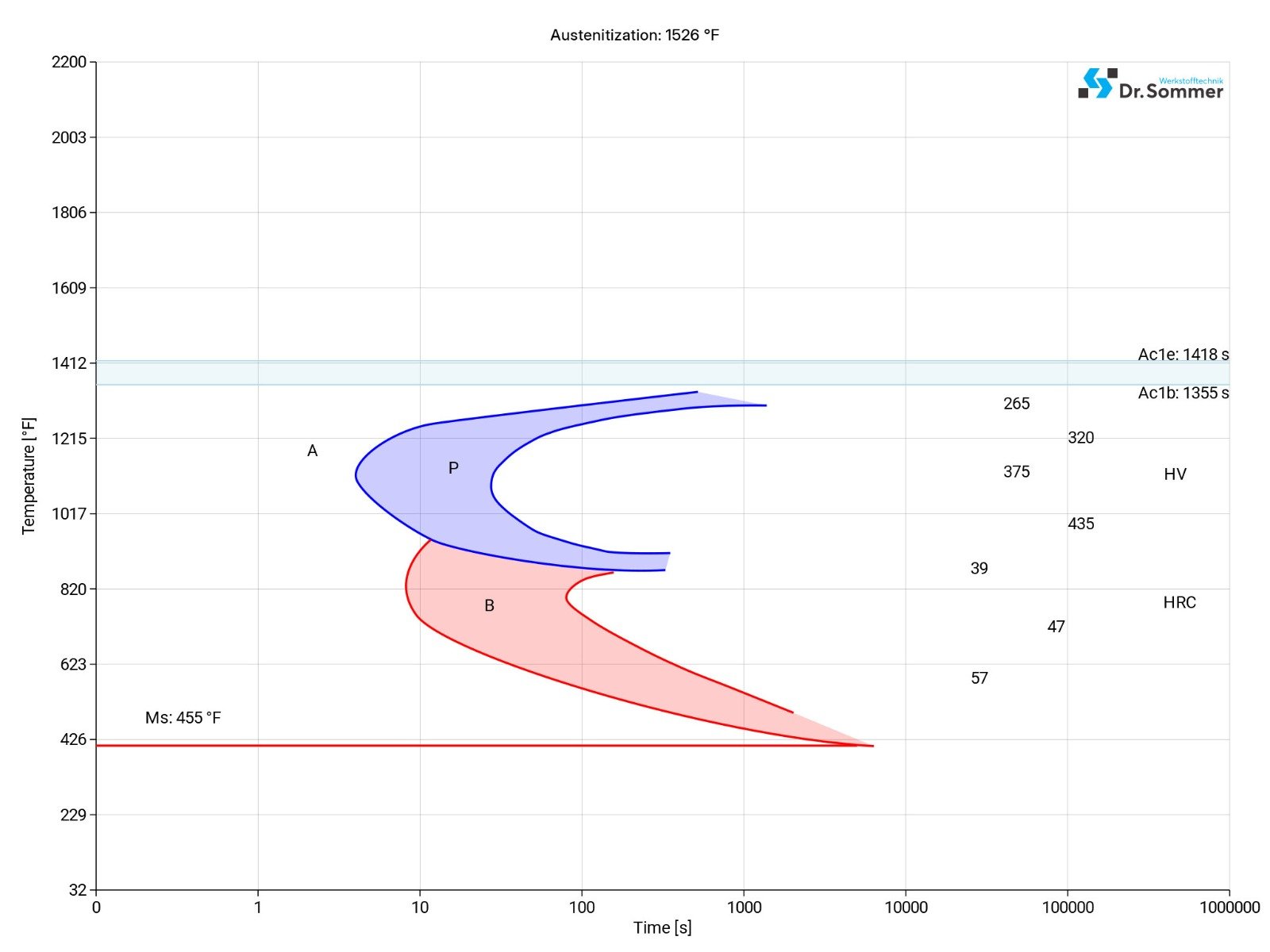

This diagram shows the structural changes at micro level over time at a constant temperature. It shows at what temperature and after what time different phases, e.g., perlite, martensite or bainite start to build.

52100 / L1 SURFACE TREATMENT

Though 52100 has a good wear resistance and toughness, applying additional surface treatments can enhance the surface and improve appearance.

This process introduces nitrogen into the surface of the material which enhances corrosion resistance and wear resistance.

Oxidizing will give the material a black finish which in turn enhances corrosion resistance.

Carburization introduces additional carbon in the surface to give the material a harder surface and better wear resistance.

To improve wear resistance and reduce friction, both advantages when this material is used for bearings, the material can be coated by PVC (Physical Vapor Deposition) or CVD (Chemical Vapor Deposition).

52100 / L1 PROCESSING

Spheroidized structures are preferred for most machining operations. To achieve improved machining performance, heat to a temperature of 1200°F (649°C) for a spheroidizing annealing process before the material is machined.

Used for intricate designs, hardened materials like 52100, wire and die-sinking EDM is advantageous. EDM does not use mechanical forces which suit the 52100 in its hardened condition and is easier to use than conventional machining processes.

Heat treatment, quenching, tempering, residual stresses but also machining, temperature changes as well as decarburization may cause dimensional changes to 52100. Proper machining and care during heat treatment may prevent dimensional changes.

This material is forged at a temperature range of 1700-2200°F (927-1205°C). Do not let the temperature drop below 1700°F (925°C) and equalize, after forging is finished, at a temperature of 1375°F (745°C) for 4 to 6 hours. Finish this process off by cooling the parts down in air.

Welding 52100 is difficult due to the high carbon content. During the welding process the heat affected site will form a martensite which leads to the risk of cracking.

With care and correct procedures welding 52100 is achievable.

The site of the weld should be cleaned, degreaced and oxidation removed. Preheating, choice of electrodes or filler to match the base metal, choosing the right welding process and a possible post weld heat treatment should be considered.

52100 / L1 APPLICATION OPTIONS

Though often used for ball bearings 52100 / L1 high carbon steel it is also used for tools, dies and molds, knife blades, machine components or precision machine parts.

• Drills

• Threading tools

• Centre lathes

• Milling cutters

• Reamers

• Small die plates

• Pressure rollers

• Cold rollings

• Measuring tools

• Cold pilger rollings

• Cold pilger jaws

• Gauges

• Mandrels

• Woodworking tools

• Cold extrusion tools

• Flanging rollers

• Shear knives

• Roller bearings

• Ball bearings (medium to large size)

52100 / L1 CONCLUSION

The 52100 / L1 is used in many different areas, from ball bearings to knives. It offers a good balance between hardness, wear resistance and toughness, giving it flexibility and good durability.

- Universally applicable

- Medium alloyed cold work steel (high hardness acceptance)

- Low hardening depth

- Good wear resistance

- Good toughnes

We offer this steel as 52100 Flat Stock.

52100 / L1 ALTERNATIVES

Are you looking for an alternative steel grade?

WE HAVE THE SOLUTION!

With the ABRAMS STEEL GUIDE, you can obtain an alternative or equivalent steel grade with just a few clicks.

52100 / L1 DATASHEET

Download the technical data sheet in PDF format here.

The data shown here has been compiled with the greatest diligence and is regularly updated with regard to the correctness and completeness of its content. The content is indicative only and should not be taken as a warranty of specific properties of the product described or a warranty of suitability for a particular purpose. All information presented is given in good faith and no liability will be accepted for actions taken by third parties in reliance on this information. ABRAMS Industries reserves the right to change or amend the information given here in full or parts without prior notice.