AISI 420 FM - Tool Steel - 1.2085 - X33CrS16 - Mold steel

AISI 420 FM - Tool Steel - 1.2085 - X33CrS16 - Mold steel

Back to Steel Overview

420FM STEEL PRICE CHART

420 FM STANDARD VALUES

C

Si

Mn

P

S

Cr

Ni

X33CrS16

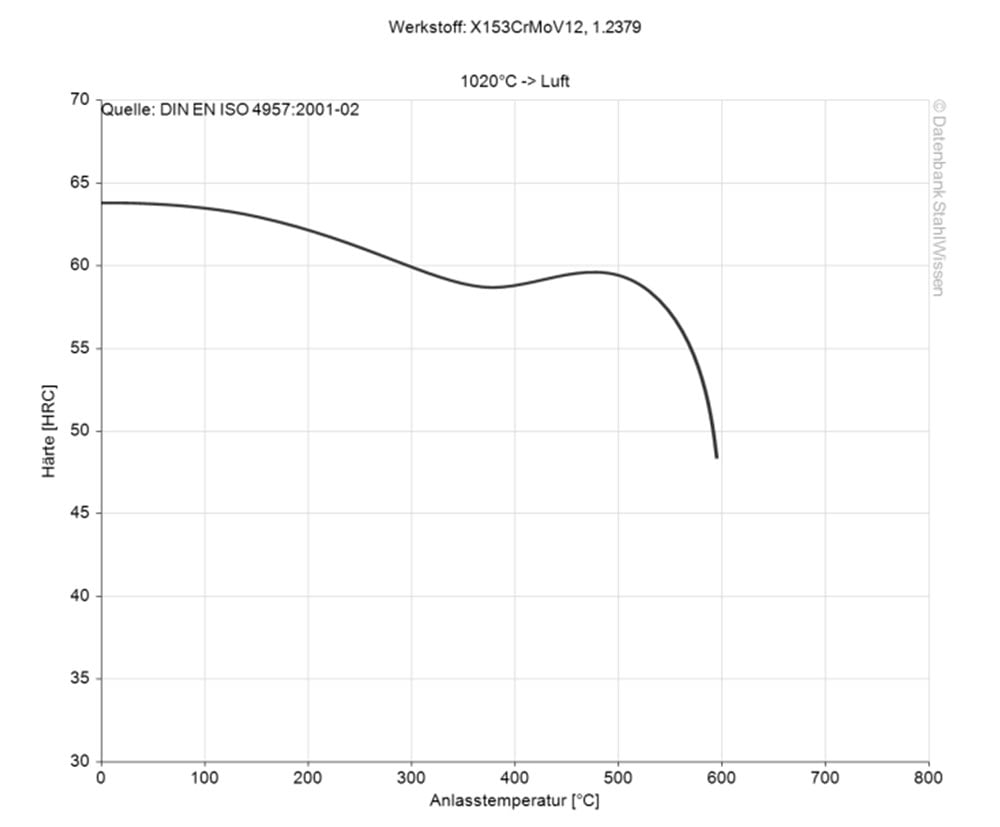

approx. 33 HRC (delivery condition) - 48 HRC

max. 330 HB

X33CrS16

approx. 33 HRC (delivery condition) - 48 HRC

max. 330 HB

420 FM PHYSICAL PROPERTIES

As a martensitic steel AISI 420FM is magnetizable, has good corrosion resistance even in humid conditions and when processing aggressive plastics. 420 FM corrosion resistant tool steel comes in a pre-hardened condition, has good machinability and high strength without the need for a heat treatment.

This steel grade can be used when good machinability with simultaneous corrosion resistance is a priority. 420 FM has a good ductility and toughness as well as good dimensional stability.

It is part of the 400 Series Stainless Steel.

To be classed as a stainless steel the steel has to have a mass fraction of at least 10.5% of chromium.

On a scale where 1 is weak and 6 is good, the corrosion resistance for 420 FM stands at 5.

Treating or polishing the surface to a high finish can prevent the possibility for rust to attach itself and spread further. Though not usual, heat treating or welding this material grade can affect the corrosion resistance.

Hot work should be done in recommended temperature ranges to avoid damages and overheating. Stress relieving might be necessary to eliminate internal stresses.

Due to the pre-hardened condition, cold working this material can be challenging and might introduce stresses that can lead to cracking, increased tool wear and greater forces might be needed to achieve the desired deformation.

420 FM TECHNICAL PROPERTIES

Though the 420 FM has some of those properties others are too low, like the edge retention for example, to make a good quality knife. Most knives require approx. 56 - 60 HRC in order to maintain a good edge and have the required toughness.

Typically the density of 420 FM tool steel is 0.28 lb/in3 (7.72g/cm3) at room temperature.

In order to reach this value, a tensile test is performed to show how much force is needed to stretch or elongate a sample before it breaks.

The thermal conductivity for tool steel 420 FM is at 23.9 W/(m*K) (166 BTU/(h-ft*°F)) at room temperature.

Medium thermal expansion coefficient | |

10-6m/(m • K) | At a temperature of |

10.25 | 68 - 212°F |

10.72 | 68 - 392°F |

11.14 | 68 - 572°F |

11.58 | 68 - 752°F |

12.02 | 68 - 932°F |

The specific heat capacity of the 420 FM tool steel at room temperature is at 0.46 J/g-°C (0.109 BTU/lb-°F).

This value shows how much heat is needed to heat 1lb of material by 1 Fahrenheit.

PERFECTION!

420 FM PROCEDURE

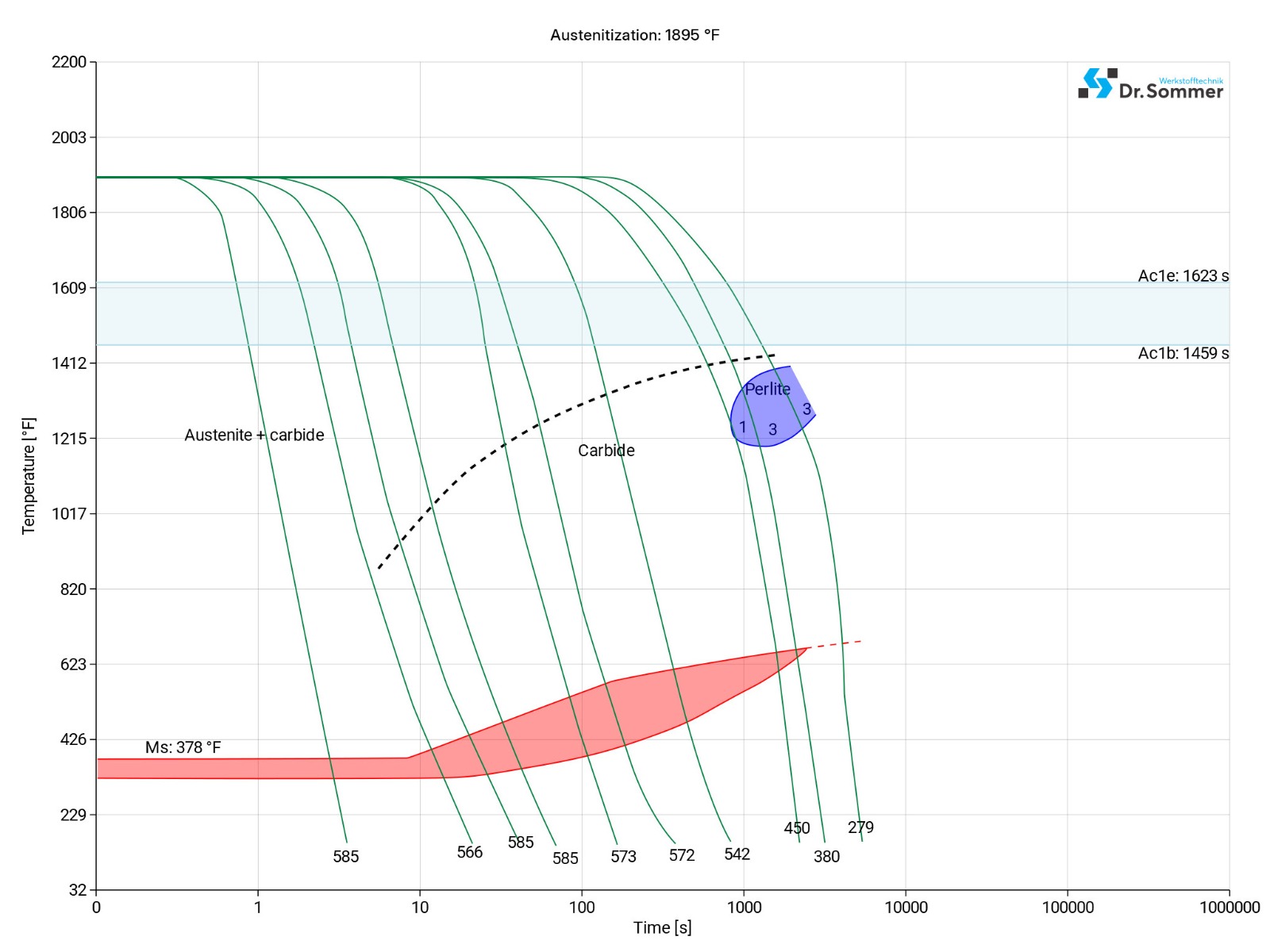

Quenching this material will transform austenite into martensite, a hard and brittle phase.

• Oil

• Compressed gas (N2)

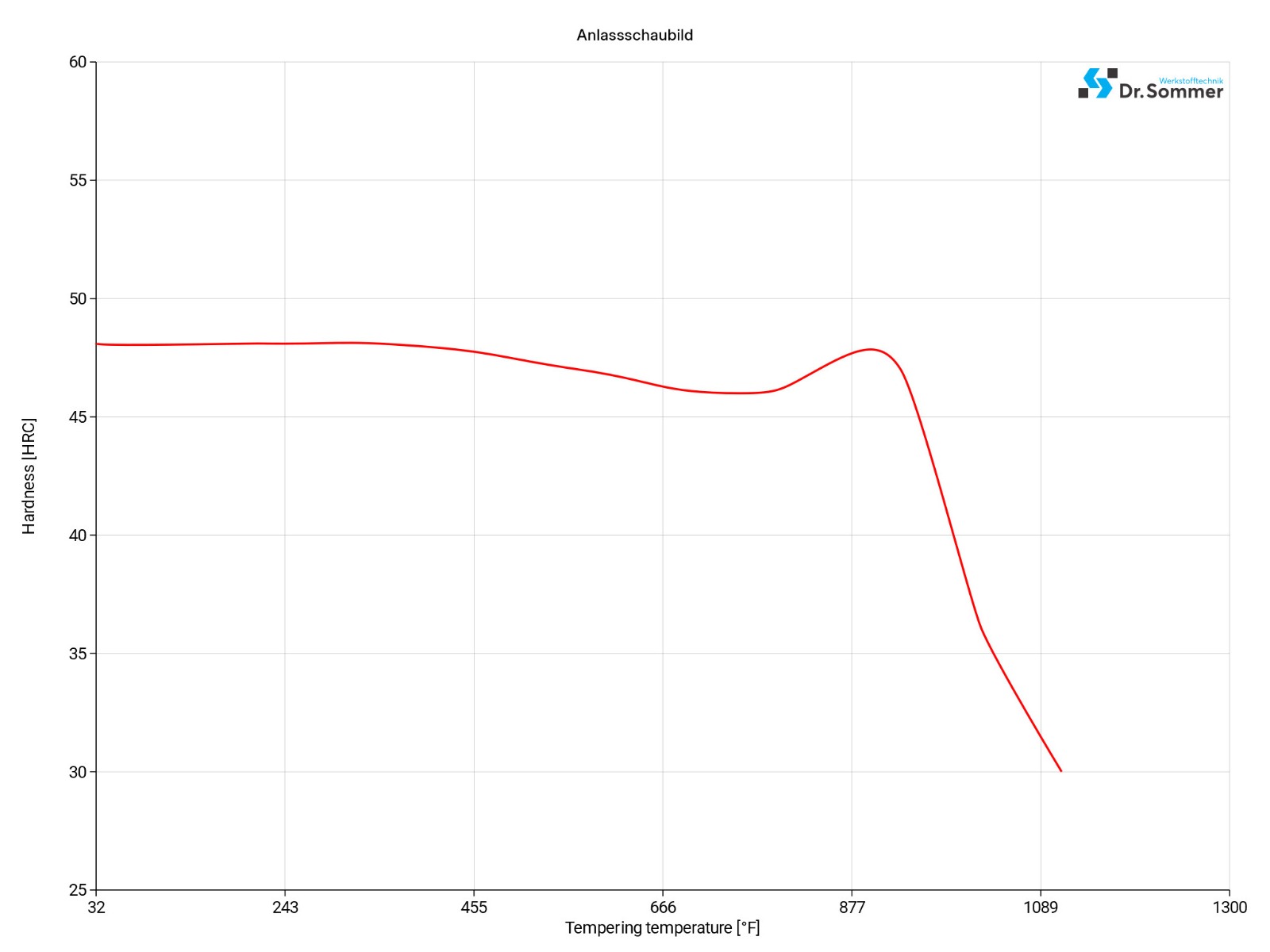

To reduce the brittleness of the phase change, after quenching, but retain the hardness achieved, heat the 420 FM slowly to a tempering temperature of 392 - 572°F (200 - 300°C), hold for 2 hours per 25/32 inch (20 mm) thickness. Double tempering is recommended. Slowly cool in the furnace.

After the quenching process some austenites can be retained. These retained austenites can be changed to martensite by sub-zero treatment.

After treating the steel at these low temperatures it is necessary to temper the material to give it a good property balance again.

Sub-zero treatment can positively affect the wear resistance, dimensional stability, hardness and strength of the 420 FM.

This diagram shows micro changes over time at different temperatures. Those are important during heat treatment as they show information about the optimum conditions for processes such as hardening, annealing and normalizing.

420 FM SURFACE TREATMENT

420 FM PROCESSING

On a scale where 1 is weak and 6 is good, the machinability of 420FM reaches a score of 5.

To prevent tool wear, cutting tools should be well maintained and kept sharp. Cutting fluids should be used to reduce friction and wear of the tool and to reduce heat created between the tool and workpiece.

After machining the 420 FM, the workpieces may need to be stress relieved, though this is less of a concern for the pre-hardened condition but can still affect and be important for continued dimensional stability of precision components.

As a pre-hardened material the 420 FM can be machined by EDM. EDM makes it possible to remove intricate and precise shapes which might be harder with conventional machining.

Polishing or heat treatment might be needed after EDM to relieve introduced stresses or to restore surface characteristics.

420 FM APPLICATION OPTIONS

Applications for this corrosion resistant tool steel include: Blow molds, packaging, electronic industry, measuring gauges, and optical instruments. Due to the better corrosion resistance, the maintenance requirement for molds is reduced.

It can be used for machine parts or medical devices which are subjected to wear or require regular cleaning or maintenance due to its hardness and wear resistance.

• Mechanical engineering

• Apparatus engineering

• Plastic processing

• Injection tools

• Base plates

• Assembling parts

• Molding frames

• Plastic molds

• Extrusion tools

• Valves

• Steam valves

• Water valves

• Fittings parts

• Pump construction

• Pump rods

• Compressor construction

• Compressor parts

• Surgical instruments

420 FM CONCLUSION

Practically, this means:

- Uniform strength

- For environments with high humidity

- Good weldability

- Is magnetic

- Is low-distortion

- Not suitable for nitriding and eroding

- Working hardness of 33 HRC in delivery condition

We offer this steel as 420 FM Flat Stock and Metric 420 FM Precision Ground Flat Stock.

420 FM ALTERNATIVES

Are you looking for an alternative steel grade?

WE HAVE THE SOLUTION!

With the ABRAMS STEEL GUIDE, you can obtain an alternative or equivalent steel grade with just a few clicks.

420 FM DATASHEET

Download the technical data sheet in PDF format here.

The data shown here has been compiled with the greatest diligence and is regularly updated with regard to the correctness and completeness of its content. The content is indicative only and should not be taken as a warranty of specific properties of the product described or a warranty of suitability for a particular purpose. All information presented is given in good faith and no liability will be accepted for actions taken by third parties in reliance on this information. ABRAMS Industries reserves the right to change or amend the information given here in full or parts without prior notice.