What is an EDM Block?

An EDM block is a specially prepared block of conductive material such as steel that serves as the workpiece for the EDM process. EDM stands for Electrical Discharge Machining.

An EDM block, also referred to as an Eroding Block, typically doesn’t pertain directly to the field of steel production or steel processing but more so to the realm of spark erosion (electro-erosive machining).

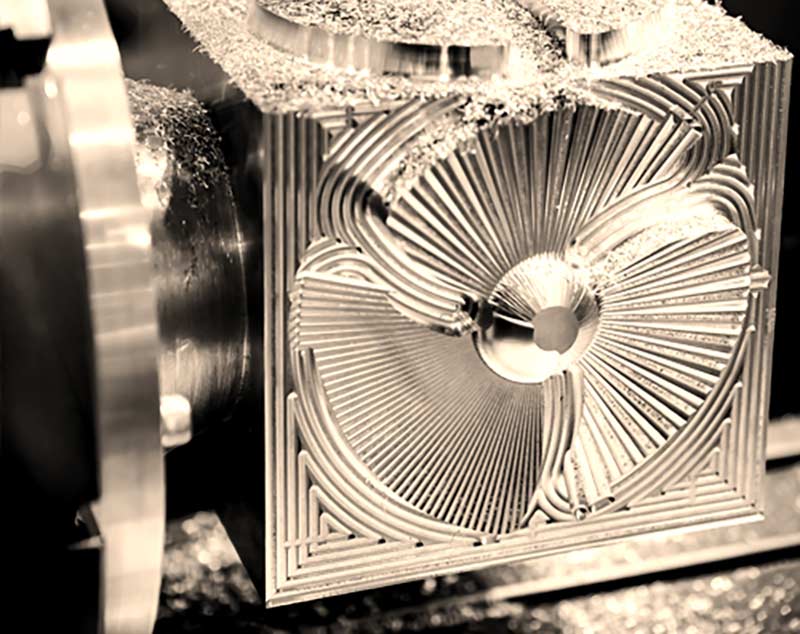

This method removes material through electrical discharges.

An EDM block, also referred to as an Eroding Block, typically doesn’t pertain directly to the field of steel production or steel processing but more so to the realm of spark erosion (electro-erosive machining).

This method removes material through electrical discharges.

Your success is our success!

Feel free to contact us.

WHAT IS AN EDM BLOCK USED FOR?

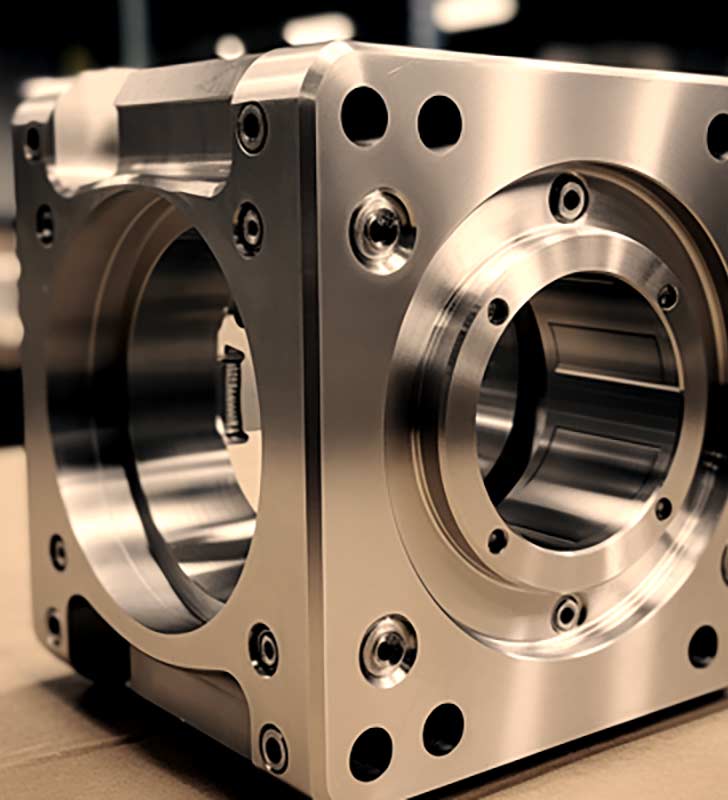

An EDM block or EDM square block is typically used in the manufacturing industry, such as in tool and mold making. In particular, tool steel is a frequently used material for EDM blocks.

Some specific applications include:

• Manufacturing of high-performance cutting tools

• Production of complex shapes

• Reference or "sacrificial piece"

Some specific applications include:

• Manufacturing of high-performance cutting tools

• Production of complex shapes

• Reference or "sacrificial piece"

HOW IS AN EDM BLOCK MADE?

The production of an EDM block (electro-discharge machining block) depends on the desired composition and specific applications, but in general, the manufacturing process follows these steps:

1. Material selection

2. Preparation of the raw material

3. Heat treatment

4. Cutting

5. Surface treatment

6. Quality control

1. Material selection

2. Preparation of the raw material

3. Heat treatment

4. Cutting

5. Surface treatment

6. Quality control

As a Steel Supplier for Hardened EDM Blocks, we not only supply standard and stock products but also offer solutions tailored to your needs, to serve the technical and commercial requirements of our customers.

Hardened Imperial EDM Blocks are often subjected to extremely high loads, and no single steel offers properties such as maximum wear resistance, hardness, and toughness. Our Steel Portfolio includes the most common steel dimensions and Steel Grades to offer an optimal combination of properties and desired size for a specific application.

It can be very frustrating to search for the optimal EDM Block Steel Grade for all your applications. We’ve got the perfect solution for this.