L3 Tool Steel - 1.2067 - 102Cr6 - SAE ~52100 - JIS ~SUJ 2

L3 Tool Steel - 1.2067 - 102Cr6 - SAE ~52100 - JIS ~SUJ 2

Back to Steel Overview

L3 STEEL PRICE CHART

L3 STEEL STANDARD VALUES

C

Si

Mn

P

S

Cr

Mo

Ni

102Cr6

60 HRC - 64 HRC

max. 223 HB

102Cr6

60 HRC - 64 HRC

max. 223 HB

L3 STEEL PHYSICAL PROPERTIES

L3 tool steel is an oil hardening cold work steel with good hardenability, wear resistance, toughness, and good cutting-edge retention as well as good impact resistance. As a medium alloyed cold work steel, L3 offers a high hardenability, however, its hardening depth is low.

L3 tool steel is not a stainless steel. Stainless steel has a mass fraction of a minimum 10.5% of chromium. L3 has a mass fraction of 1.35 - 1.6% which means it is not a stainless steel.

To be classed a corrosion resistant steel it needs a chrome content of a minimum of 10.5%. With a mass fraction of 1.35 - 1.6% can not be classed as corrosion resistant.

102Cr6 Steel (L3) is ferromagnetic and can be magnetized and is suitable for magnetic clamping.

The wear resistance for tool steel L3 is 4 on a scale where 1 is low and 6 is high.

L3 STEEL TECHNICAL PROPERTIES

Tool steel L3 can be used for knife making as it has a good balance of wear resistance, hardness and toughness. Knives made from L3 have good edge retention and they are resistant to chipping and breaking with normal use. As the L3 corrosion resistance is not high enough it is important to prevent rusting and limiting use in humid and corrosive environments. Regular maintenance should be applied to prevent corrosion and dulling of the blade.

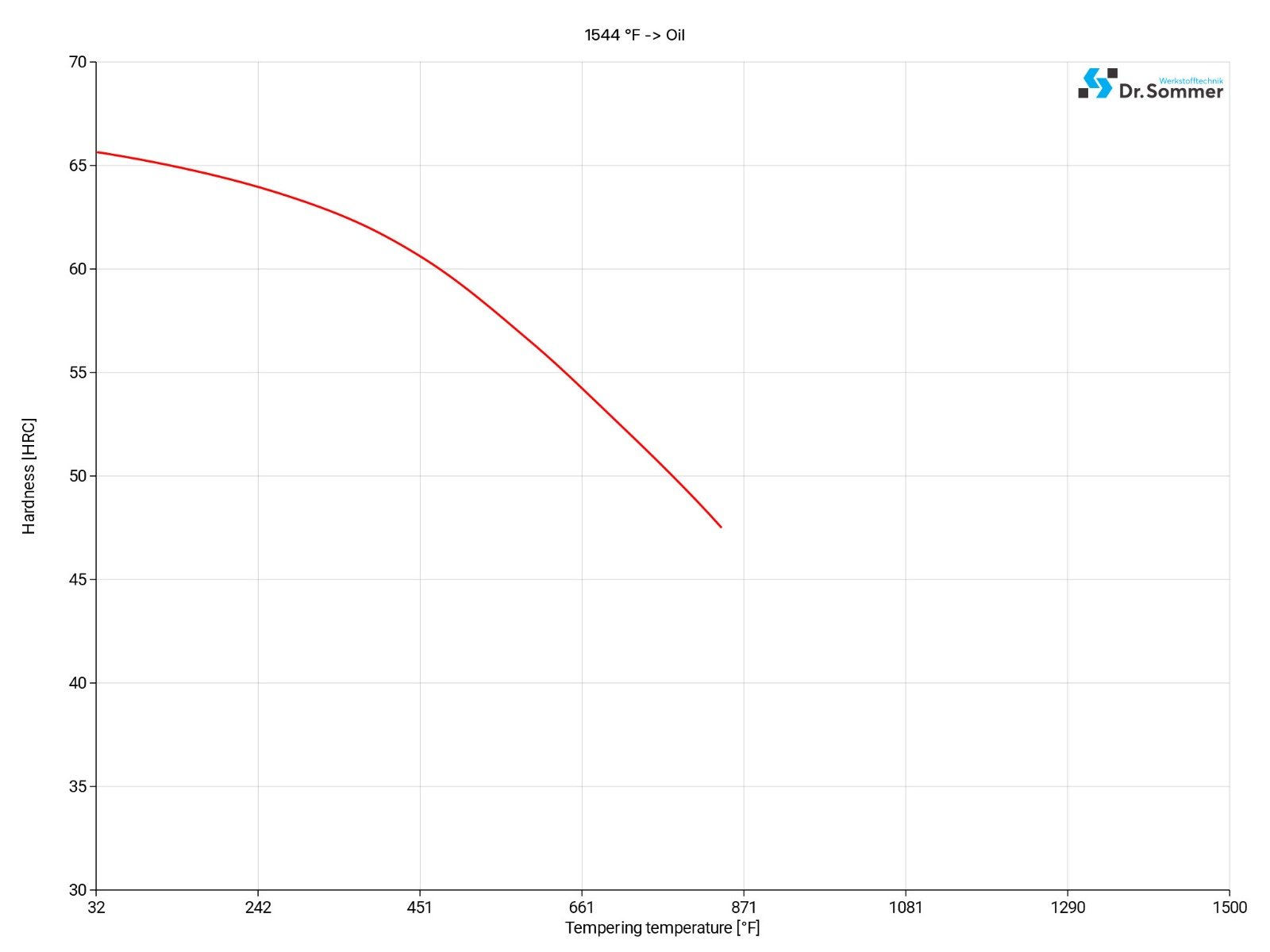

The working hardness for tool steel L3 is at 627 - 695 BHN (60 - 64 HRC).

Typically the density of tool steel L3 is 0.284 lb/in3 (7.85g/cm3) at room temperature.

The tensile strength for tool steel L3 is approx. 108.7 KSI (0.145KSI = 1MPa). This value is the result from a tensile test to show how much force is needed before the material starts to stretch or elongate before it breaks.

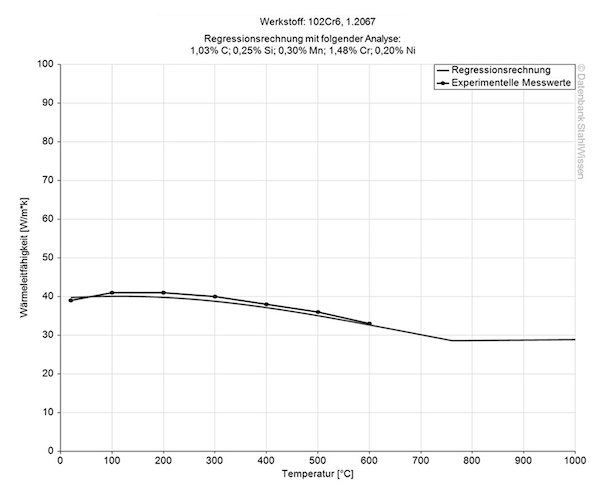

The heat conductivity for L3 Tool Steel is at 33.0 W/(m*K) (229 BTU/(h-ft*°F)) at room temperature.

Heat conductivity table | |

Value | By temperature |

33.0 | 68°F |

32.2 | 662°F |

31.4 | 1292°C |

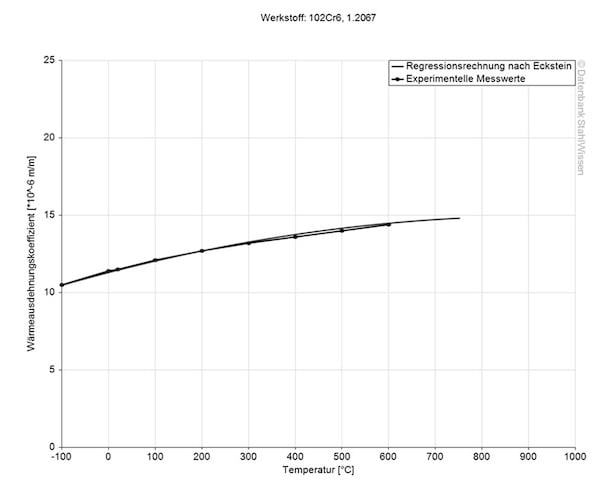

The following table shows expansion or contraction at various temperatures, which may be very important for high temperature works or when working with high temperature changes.

Medium thermal expansion coefficient | |

10-6m/(m • K) | At a temperature of |

12.3 | 68 - 212°F |

13.4 | 68 - 392°F |

13.7 | 68 - 572°F |

14.1 | 68 - 752°F |

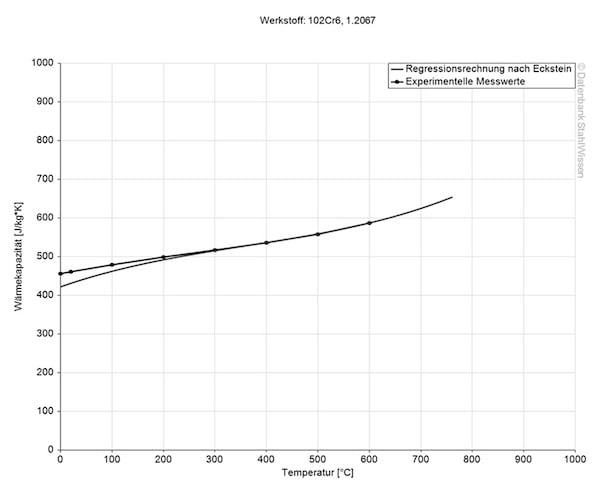

The specific heat capacity of the L3 steel at room temperature is 0.439 J/g-°C (0.105 BTU/lb-°F). This value shows how much heat is needed to heat 1lb of material by 1 Fahrenheit.

PASSION!

L3 STEEL PROCEDURE

To anneal L3 tool steel, heat the parts uniformly to a temperature of 1382 - 1472°F (750 - 800°C), following this with a slow cooling of the material in the furnace.

Heat the material uniformly to a temperature of 1598 - 1652°F (870 - 900°C) and then cool in air.

The work piece is heated uniformly to a temperature of 1112 - 1202°F (600 - 650°C) and hold for 1 - 2 hours at the temperature. Then cool, to start off with, in the furnace and follow it up with cooling in air.

Heat the L3 tool steel parts slowly to a temperature range of 1472 - 1598°F (800 - 870°C). The holding time for this material is 65 minutes per inch (25.4 mm) of thickness. To avoid loss of hardness, the material has to be transferred quickly from the furnace to the oil.

The choice of quenching medium and quenching rate can be critical and uneven quenching might lead to warping or cracking. Below are the quenching mediums listed for tool steel L3.

• Water for a temperature of up to 1526°F (830°C) and above that temperature with the following

• Oil, 356 - 428°F (180 - 220°C)

• Hot bath, 356 - 428°F (180 - 220°C)

After quenching the L3 is very hard but with high hardness the material can be very brittle. The balance of hardness and toughness can be restored by tempering tool steel L3. Slowly and uniformly heat the L3 to the chosen tempering temperature and hold for 2 hours.

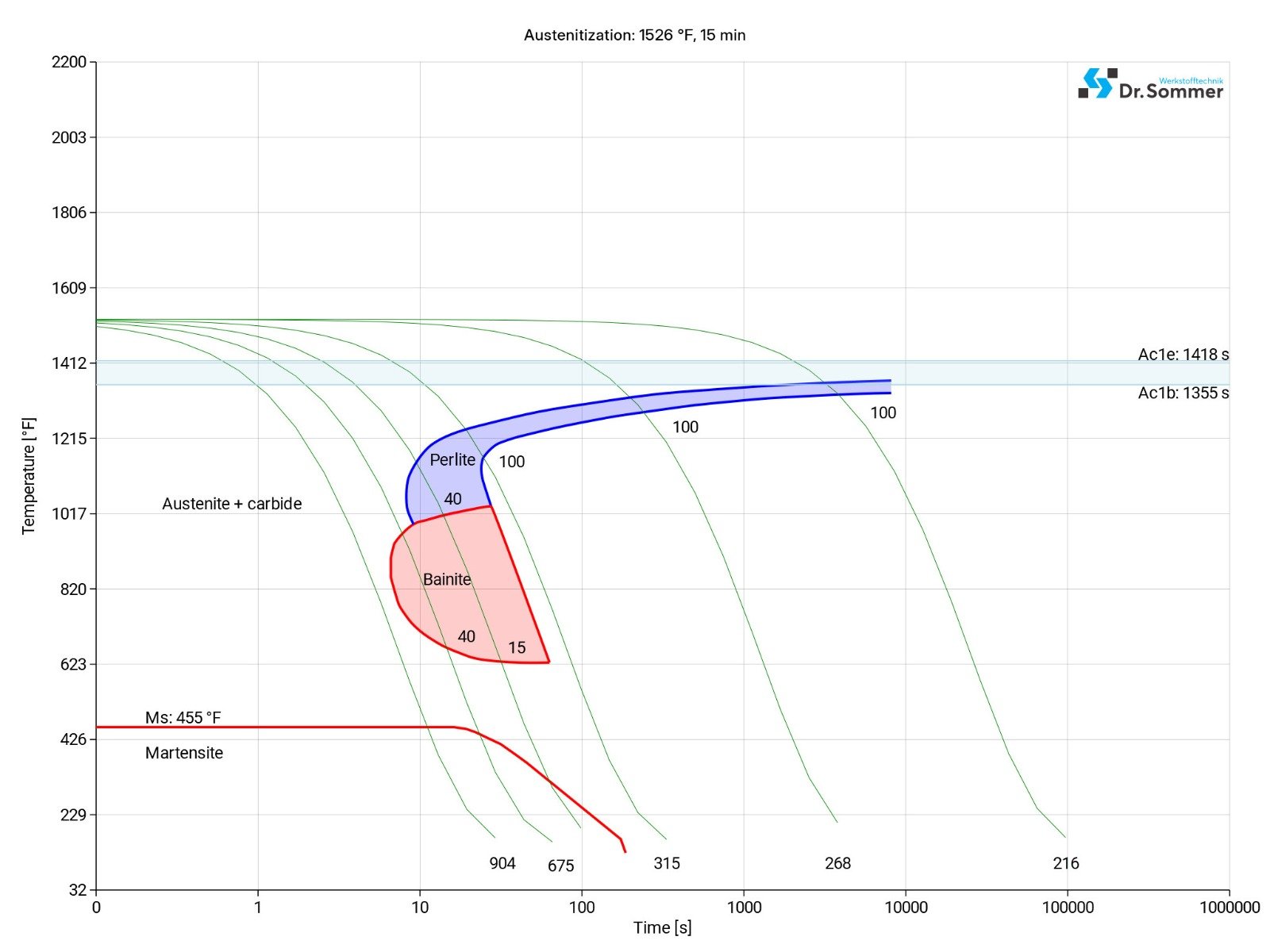

This diagram shows micro changes over time at different temperatures. Those are important during heat treatment as they show information about the optimum conditions for processes such as hardening, annealing and normalizing.

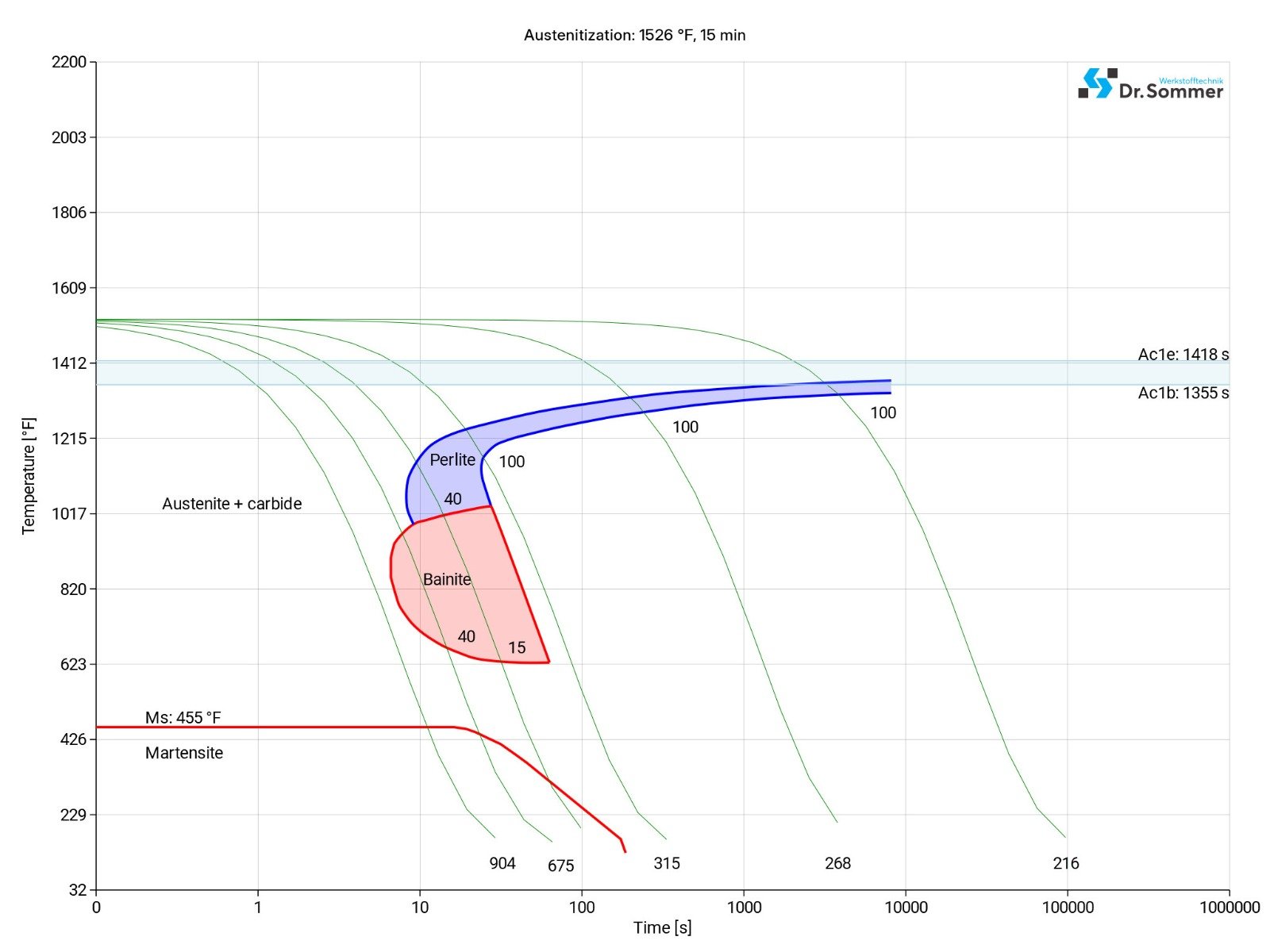

This diagram shows the structural changes at micro level over time at a constant temperature. It shows at what temperature and after what time different phases, e.g., perlite, martensite or bainite start to build.

L3 TOOL STEEL PROCESSING

EDM can be advantageous when machining complex shapes, intricate details or to achieve tight tolerances. The right parameters and right electrode should be considered when using EDM for material removal. EDM generates heat which can affect the microstructure of the L3. Post heat treatment can be done to relieve added stresses and restore the materials properties. EDM may leave a rougher surface with a recast layer which can be removed by stoning and polishing.

As for all materials, the L3 Steel expands and contracts with heating and cooling. Uneven heating or cooling can lead to warping or distortion.

Dimensional changes can occur during phase changes, stress relief, grain growth or decarburization. To control dimensional changes it is important to use precise temperatures and cooling methods as well as a precise process to release stresses without affecting properties and without causing dimensional changes. Equipment should be monitored and maintained so that they are able to work to the highest standards possible.

L3 tool steel grade is not suitable for welding.

L3 STEEL APPLICATION OPTIONS

L3 finds its uses in a wide range of industries and applications, like in the wood and paper industry for paper cutters and circular saw blades. As it reliably retains its dimensions it is also well suited for measuring tools, e.g., a caliper.

Apart from roller- and ball bearings this steel grade can also be used for drills, thread taps and threading dies.

• Drills

• Threading tools

• Centre lathes

• Millung cutters

• Reamers

• Small die plates

• Pressure rollers

• Cold rollings

• Measuring tools

• Cold pilger rollings

• Cold pilger jaws

• Gauges

L3 STEEL CONCLUSION

Tool steel L3 can be used in a variety of applications from bearings to knives, it offers a good balance of hardness, wear resistance and toughness lending it durability and longevity. Care when heat treating this steel grade should be taken to achieve desired mechanical properties and its hardness should be considered when machining or sharpening knives.

- Universally applicable

- Medium alloyed cold work steel (high hardness acceptance)

- Low hardening depth

- Good wear resistance

- Good toughness

We offer this steel as L3 Flat Stock.

L3 STEEL ALTERNATIVES

Are you looking for an alternative steel grade?

WE HAVE THE SOLUTION!

With the ABRAMS STEEL GUIDE, you can obtain an alternative or equivalent steel grade with just a few clicks.

L3 STEEL DATASHEET

Download the technical data sheet in PDF format here.

The data shown here has been compiled with the greatest diligence and is regularly updated with regard to the correctness and completeness of its content. The content is indicative only and should not be taken as a warranty of specific properties of the product described or a warranty of suitability for a particular purpose. All information presented is given in good faith and no liability will be accepted for actions taken by third parties in reliance on this information. ABRAMS Industries reserves the right to change or amend the information given here in full or parts without prior notice.