314 Stainless Steel - 1.4841 - X15CrNiSi25-21 - ~SUH 310

314 Stainless Steel - 1.4841 - X15CrNiSi25-21 - ~SUH 310

Back to Steel Overview

314 STEEL PRICE CHART

314 STANDARD VALUES

C

Si

Mn

P

S

Cr

Ni

N

X15CrNiSi25-21

approx. 223 BHN

max. 223 HB

X15CrNiSi25-21

approx. 223 BHN

max. 223 HB

314 PHYSICAL PROPERTIES

314 is an austenitic, heat resistant stainless steel. The addition of silicon, among other alloys, in 314 stainless makes this steel grade more resistant to oxidation and prevents carburization at elevated temperatures.

On the other hand, continuous use at a temperature range of 1202 - 1652°F (650 - 900°C) makes this stainless steel more susceptible to phase changes and embrittlement. This material grade is suitable for cold forming and cold heading, hammer- and die forging and is not magnetizable.

To be classified as stainless steel the material has to have a minimum of 10.5% chromium. 314 has a mass fraction of 24 - 26%. It is a part of the 300 Series Stainless Steel.

On a scale where 1 is weak and 6 is good, the corrosion resistance for 314 stands at 6.

It shows limitations in more aggressive environments like with chloride ions. For those environments stainless steels with added molybdenum are better suited.

In aggressive environments, containing chloride for example, the 314 is not as resistant and can be susceptible to stress corrosion cracking.

Above 1652°F (900°C), 314 has only limited corrosion resistance to carburizing gasses or low-oxygen gasses with nitrogen content.

Cold working, welding and in specific conditions and prolonged exposure to high temperatures the material can become slightly magnetic. This material grade is not suitable for magnetic clamping.

Heat the workpiece slowly and uniformly to a temperature range of 1742 - 2192°F (1200 - 950°C) and carry out the hot work.

Do not let the temperature drop below 1832°F (1000°C) and use an annealing treatment after hot forming, especially if the temperature dropped below 1832°F during hot working the material.

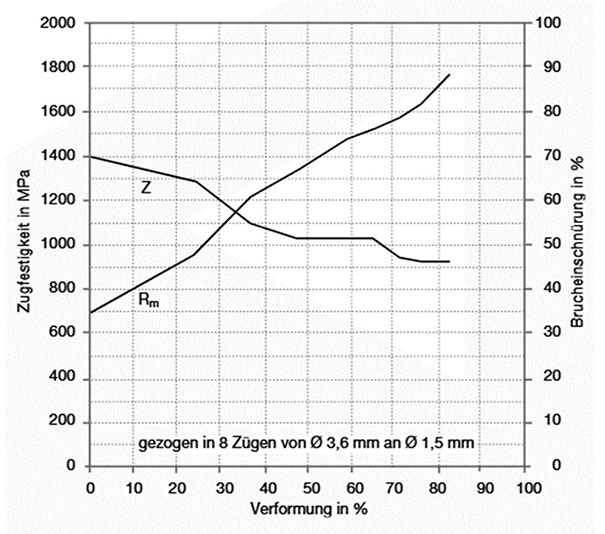

Due to its austenitic structure, which makes the material more ductile, 314 stainless steels can be easily cold worked.

Parts that have been exposed to high temperatures, 1202 - 1652°F (650 - 900°C), over a long time are not recommended to be cold worked as the material becomes susceptible to intergranular carbide precipitation as well as intermetallic phase precipitation.

314 TECHNICAL PROPERTIES

As an austenitic steel the 314 can only be hardened by cold working it and for a good edge as well as good edge retention knife steel should be hardened and have a relatively high carbon content.

Typically the density of stainless steel 314 is 0.285 lb/in3 (7.9 g/cm3) at room temperature.

The thermal conductivity for stainless steel 314 is 15 W/(m*K) (104 BTU/(h-ft*°F)) at room temperature.

314 is a heat resistant stainless steel with good oxidation and excellent chemical resistance at temperatures of up to 2012°F (1100°C).

However, the corrosion resistance of this heat resistant steel is restricted in certain atmospheres (please see corrosion resistance).

Medium thermal expansion coefficient | |

10-6m/(m • K) | At a temperature of |

~ 17 | 68 - 752°F |

~ 18 | 68 - 1472°F |

~ 19 | 68 - 1832°F |

~ 19.5 | 68 - 2192°F |

The specific heat capacity for the 314 stainless steel at room temperature is 0.5 J/g-°C (0.119 BTU/lb-°F). This value shows how much heat is needed to heat 1lb of material by 1 Fahrenheit.

Table of the specific electrical resistivity | |

Value | At a temperature of |

~ 0.9 (Ohm*mm²)/m | 68°F |

PREMIUM QUALITY – OUR HIGHEST STANDARD!

314 PROCEDURE

Austenitic steel gets quenched to prevent the formation of chromium carbides and to ensure the optimal corrosion resistance.

Unlike martensitic steels, austenitic steels do not harden when quenched. Quenching should always be done with desired applications and next steps in mind.

• Water

• Air

Sub-zero treatment is often done to change martensite to austenite.

The 314, already an austenite, can benefit from this treatment to stabilize the austenitic structure as well as improve mechanical properties, stress relief or to enhance corrosion resistance.

314 SURFACE TREATMENT

Here a selection of surface treatments that can be used for the 314:

To polish this material make sure all debris has been removed from the surface so as not to scratch the surface during polishing. Be sure not to over polish the material and to use the correct polishing tools and aids.

Polishing stainless steel removes minute contaminants from the surface that could be the source of a starting point for corrosion.

Laser texturing can precisely texture certain areas by removing material from the workpiece with the pulse action of the laser.

Electrochemical texturing is done by connecting a substrate as a positive electrode in an electrochemical cell.

The electrolyte is being agitated resulting in electrochemically etched pits.

314 PROCESSING

On a scale where 1 is weak and 6 is good, the machinability of 314 reaches a score of 2.

The formation of carbides, in 314, can increase the wear of cutting tools. Due to severe work hardening and poor thermal conductivity, adequate cooling and high quality tooling is required.314 stainless steels should be machined at a low cutting speed with shallow cutting depths.

Considering these changes is important when tight dimensional tolerances are important to finished parts.

As austenitic steels in comparison to unalloyed steels only have a 30% thermal conductivity and a lower fusion point, austenitic steels should be welded with a lower heat input than unalloyed steels.

To avoid burn through or overheating of thinner parts it is recommended to apply a higher welding speed. 314 stainless steels have a much higher coefficient of thermal expansion than unalloyed steels. Combined with poorer thermal conductivity greater distortion is to be expected.

314 APPLICATION OPTIONS

Stainless steel 314 can be used at high temperatures up to 2012°F (1100°C) and is resistant to oxidation which makes it ideal for furnace components, ore processing and kiln components as well as heat treatment equipment like heat retorts and heat conductors.

In high temperatures the material does not go soft or brittle which is beneficial when using the 314 in heat exchangers with aggressive atmospheres, high temperature oxidation and carburization.

The 314 can resist creep (a deformation over an extended time at elevated temperatures and high, constant stress) in high temperatures and for extended periods.

• Apparatus engineering for high temperature application

• Automotive industry

• Chemical industry

• Oil industry

• Chains for the cement and concrete industry

• Mechanical engineering

• Furnace construction

• Annealing muffles

• Enamel grates

• Fire baskets

• Heat conductors

314 CONCLUSION

- Heat resistant

- Chromium-nickel-molybdenum steel

- Resistant to oxidation at high temperatures

- Good strength properties

- Excellent chemical resistance at high temperatures up to 1100 °C

- Very good corrosion resistance

- Creep resistant at high temperatures

- Non-magnetizable

We offer this steel as 314 Flat Stock.

314 ALTERNATIVES

Are you looking for an alternative steel grade?

WE HAVE THE SOLUTION!

With the ABRAMS STEEL GUIDE, you can obtain an alternative or equivalent steel grade with just a few clicks.

314 DATASHEET

Download the technical data sheet in PDF format here.

The data shown here has been compiled with the greatest diligence and is regularly updated with regard to the correctness and completeness of its content. The content is indicative only and should not be taken as a warranty of specific properties of the product described or a warranty of suitability for a particular purpose. All information presented is given in good faith and no liability will be accepted for actions taken by third parties in reliance on this information. ABRAMS Industries reserves the right to change or amend the information given here in full or parts without prior notice.