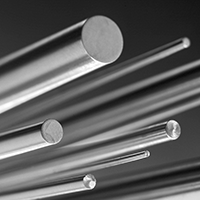

Decarb Free Rounds

Decarb Free Rounds (DCF) are steel rods or round bars that are 100% free from decarburization and are manufactured without a decarbonized or oxidation-prone surface layer.

Carbon loss on the surface of the steel affects its properties, especially its hardness and strength. Decarb Free steel rounds are oversized to finish to nominal diameter.

→ Decarb Free Rounds - less post-processing - save costs.

Carbon loss on the surface of the steel affects its properties, especially its hardness and strength. Decarb Free steel rounds are oversized to finish to nominal diameter.

→ Decarb Free Rounds - less post-processing - save costs.

Your success is our success!

Feel free to contact us.

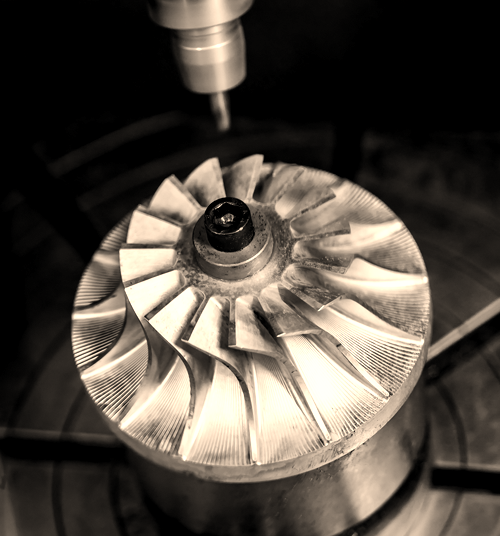

WHAT ARE DECARB FREE ROUNDS USED FOR?

Decarb Free Rounds are also referred to as Decarburized Rounds and are used in areas where it is important that the steel's surface has uniform mechanical properties across its entire cross-section.

Some applications of Decarb Free Rounds include:

• Tool making

• Machinery construction

• Precision parts

Some applications of Decarb Free Rounds include:

• Tool making

• Machinery construction

• Precision parts

HOW ARE DECARB FREE ROUNDS MADE?

The process for making Decarb Free Rounds primarily involves the following basic steps:

• Steel selection

• Decarburization

• Cutting and sawing

• Surface finishing

• Quality control

• Steel selection

• Decarburization

• Cutting and sawing

• Surface finishing

• Quality control

As a Decarb Free Round Steel Supplier, we not only supply standard and stock products but also offer custom solutions tailored to your needs, serving the technical and commercial requirements of our customers.

DCF Steel Round Rods are often exposed to extremely high stresses, and no single steel possesses properties such as maximum wear resistance, hardness, and toughness. Our steel portfolio includes the most common steel dimensions and grades, allowing us to offer an optimal combination of properties and desired size for a specific application.

It can be very frustrating to search for the optimal oversized Decarb Free Round Bar Steel Grade for all your applications. We’ve got the perfect solution for this.