Toolox 33 Engineering and Tool Steel - Quenched and tempered

Toolox 33 Engineering and Tool Steel - Quenched and tempered

Back to Steel Overview

TOOLOX 33 STEEL PRICE CHART

TOOLOX 33 STANDARD VALUES

C

Si

Mn

P

S

Cr

Mo

Ni

V

Toolox 33

approx. 30 HRC - 36 HRC (delivery condition, without nitriding)

max. 330HB

Toolox 33

approx. 30 HRC - 36 HRC (delivery condition, without nitriding)

max. 330 HB

TOOLOX 33 PHYSICAL PROPERTIES

Toolox 33 comes with a lot of plus points like the very low residual stresses, high impact toughness and crack resistance. Due to the low carbon and alloy content this tool steel material is suitable for both welding and thermos-cutting.

With the ability to nitrate this material the surface hardness can be additionally increased and service life extended. The combination of those characteristics makes Toolox 33 suitable for construction and wear parts and other mechanical components as well as plastic and rubber injection molds. It may also be polished and etched with exceptional results.

On a scale where 1 is weak and 6 is good, the corrosion resistance for Toolox 33 stands at 2.

To be corrosion resistant a steel needs to have a mass fraction of a minimum of 10.5% chromium to be classed stainless steel and therefore be corrosion resistant.

With the combination of high strength, fatigue resistance and toughness, Toolox 33 is used in cold work for forming, bending, and drawing but also finds its uses in components like guide plates, support plates and staple holder plates.

TOOLOX 33 TECHNICAL PROPERTIES

The yield strength shows how much stress can be applied to a material before it plastically deforms. Beyond that point the material will not return to its original form if the stresses are taken away but will stay deformed or even break.

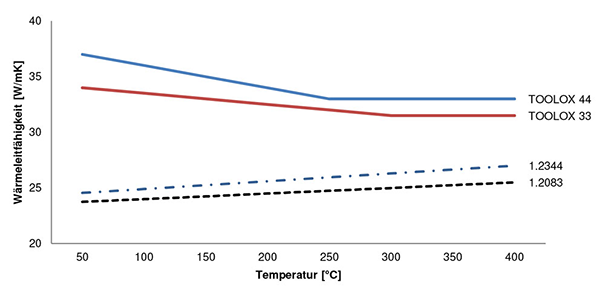

The heat conductivity for Toolox 33 is at 35.0 W/(m*K) (243 BTU/(h-ft*°F)) at room temperature.

Heat conductivity table | |

Value | By temperature |

35.0 | 68°F |

35.0 | 392°F |

30.0 | 572°F |

23.0 | 1112°F |

BECOME EVEN BETTER WITH ABRAMS PREMIUM STEEL® THAN YOUR COMPETITORS SUSPECT!

TOOLOX 33 PROCEDURE

Any further heat treatment of this steel grade has to be considered very well to preserve the given properties of this grade by the manufacturer.

To preserve those properties one has to have a detailed understanding of the metallurgy of the Toolox 33 and how the heating process may change its properties.

Toolox 33 is tempered (delivery condition) at 1094°F (590°C), this removes all residual stresses and allows excellent precision when machining.

TOOLOX 33 SURFACE TREATMENT

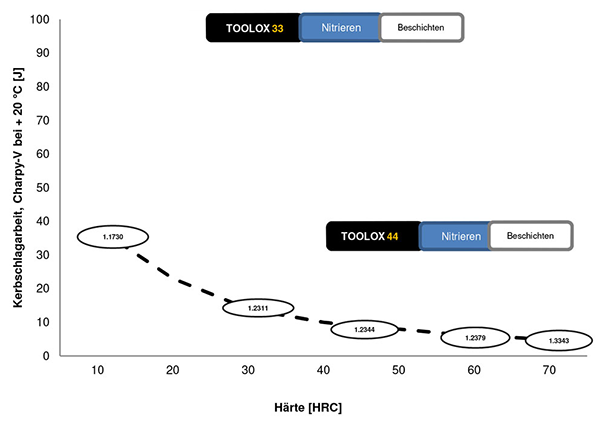

For applications needing better surface properties, Toolox 33 can be induction or laser hardened and nitrited.

This gives Toolox 33 a high surface hardness with a very resistant core, increased fatigue resistance and therefore a longer service life.

Note: Any surface treatment should not exceed the temperature of 1094°F (590°C).

If PVD (Physical Vapor Deposition) coating, the nitrided surface, an even higher surface hardness as well as a corrosion resistance can be reached. Toolox 33 can reach a surface hardening of 700 HV with this procedure and a hardening depth of 1/64 to 5/64 inches (0.2 to 2mm).

Note: Any surface treatment should not exceed the temperature of 1094°F (590°C).

TOOLOX 33 PROCESSING

On a scale where 1 is weak and 6 is good, the machinability of Toolox 33 reaches a score of 4.

Selecting the correct process, finishing requirements, power input as well as electrodes and dielectric fluid is important for any steel.

As Toolox 33 is produced to have certain properties, it is very important to ensure that the process is planned and controlled to maintain the intrinsic properties and to meet the specifications of the intended application.

Toolox 33 can be welded by all conventional methods and can be joined to any other kinds of weldable steels.

Before welding the base metal should be cleaned from contaminants such as grease, rust, oil and moisture and sharp edges removed. Consumables suitable for Toolox are stainless, unalloyed, and low-alloyed consumables.

TOOLOX 33 APPLICATION OPTIONS

Toolox 33 can be used in engineering and tooling due to its wear resistance, durability, dimensional stability (as well under high temperatures) and toughness for molds, die casting, stamping and forging.

Due to its surface hardness, impact strength and wear resistance it can be used for machine components.

The former properties make the Toolox 33 useful for mining equipment, wear plates, pump parts, wind turbines, gears and armor plates as well as shredders and for manufacturing agricultural equipment like plough sheares.

• Mechanical engineering

• Machine parts

• Guide rails

• Base plates

• Assembling parts

• Press brake tools

• Plate forming tools

• Wear parts

• Plastic molds

• Molding frames

• Forming tools

• Rubber molds,

• Die casting molds

TOOLOX 33 CONCLUSION

The tempered material can optimize the manufacturing process and thus reduce costs. Toolox 33 also has properties such as good wear resistance, good dimensional stability and good machinability, which make machining this material grade a good choice for many applications where precise dimensions and tolerances, durable performance in abrasive environments and a good balance between wear resistance and ease of processing are required.

Practically, this means:

- It is easy to polish

- Grainable

- Erodible

- Etchable

- Autogenous cutting

- Weldable

- Nitridable

- Hard chromium platable

- Working hardness is 30 - 36 HRC

We offer this steel as Toolox 33 Flat Stock.

TOOLOX 33 ALTERNATIVES

Are you looking for an alternative steel grade?

WE HAVE THE SOLUTION!

With the ABRAMS STEEL GUIDE, you can obtain an alternative or equivalent steel grade with just a few clicks.

TOOLOX 33 DATASHEET

Download the technical data sheet in PDF format here.

The data shown here has been compiled with the greatest diligence and is regularly updated with regard to the correctness and completeness of its content. The content is indicative only and should not be taken as a warranty of specific properties of the product described or a warranty of suitability for a particular purpose. All information presented is given in good faith and no liability will be accepted for actions taken by third parties in reliance on this information. ABRAMS Industries reserves the right to change or amend the information given here in full or parts without prior notice.