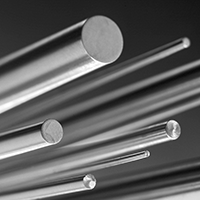

Cold Finished Rounds

Cold Finished Rounds (CF) are cold drawn round steels. These metal bars are produced through a cold deformation process. As a result, the steel gets a smoother surface, improved mechanical properties, and tighter tolerances compared to hot-rolled round steels.

To achieve the surface quality and tight tolerances, Cold Finished Rounds are cold drawn, smoothly turned, ground, or ground and polished.

→ Cold drawing - Pulling the steel through a die set.

To achieve the surface quality and tight tolerances, Cold Finished Rounds are cold drawn, smoothly turned, ground, or ground and polished.

→ Cold drawing - Pulling the steel through a die set.

Your success is our success!

Feel free to contact us.

ADVANTAGES OF COLD FINISHED ROUNDS

• Cold drawing can achieve very precise size and roundness tolerances.

• Cold-processed steels have a smoother and cleaner surface compared to hot-rolled steels.

• The cold-processing method alters the microstructure of the steel, leading to an increase in tensile strength and yield point.

• In some cases, Cold Finished Rounds can offer improved machinability compared to their hot-rolled counterparts.

• Cold-processed steels have a smoother and cleaner surface compared to hot-rolled steels.

• The cold-processing method alters the microstructure of the steel, leading to an increase in tensile strength and yield point.

• In some cases, Cold Finished Rounds can offer improved machinability compared to their hot-rolled counterparts.

HOW ARE COLD FINISHED ROUNDS MADE?

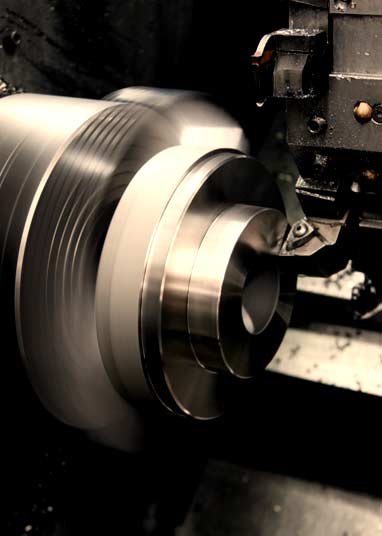

Cold Finished Rounds are manufactured in a cold forming process. Cold drawing refers to the mechanical forming process of steel where the material is processed at room temperature. As a result, the diameter of the round steel is reduced and the surface quality is improved.

The cold drawing process essentially includes the following steps:

1. Raw material: Shape steel by hot rolling into a suitable form

2. Drawing bench: Insert steel into a drawing machine

3. Drawing through a die: Steel is shaped into the desired cross-section

4. Increasing strength: Crystal lattice structures of the steel are realigned and compressed

5. Straightening and cutting: Ensuring the steel is straight

6. Finishing: The steel is smoothly turned, ground, or ground and polished.

The cold drawing process essentially includes the following steps:

1. Raw material: Shape steel by hot rolling into a suitable form

2. Drawing bench: Insert steel into a drawing machine

3. Drawing through a die: Steel is shaped into the desired cross-section

4. Increasing strength: Crystal lattice structures of the steel are realigned and compressed

5. Straightening and cutting: Ensuring the steel is straight

6. Finishing: The steel is smoothly turned, ground, or ground and polished.

As a Steel Supplier for CF Round Bars in Imperial and Metric Steel Sizes, we not only supply standard and stock products but also offer solutions specifically tailored to your needs, serving the technical and commercial requirements of our customers.

CF Steel Round Bars are often subjected to extremely high loads, and no single steel possesses properties such as maximum wear resistance, hardness, and toughness. Our steel portfolio includes the most common steel dimensions and steel grades, to offer an optimal combination of properties and desired size for a specific application.

It can be very frustrating to search for the optimal imperial Cold Finished Round Bar Steel Grade for all your applications. We’ve got the perfect solution for this.