303 Stainless Steel - DIN 1.4305 - X8CrNiS18-9 - ~SUS 303

303 Stainless Steel - DIN 1.4305 - X8CrNiS18-9 - ~SUS 303

Back to Steel Overview

303 STEEL PRICE CHART

303 STANDARD VALUES

C

Si

Mn

P

S

Cr

Ni

Cu

N

X8CrNiS18-9

215 HB - 250 HB (delivery condition)

max. 250 HB

X8CrNiS18-9

215 HB - 250 HB (delivery condition)

max. 250 HB

303 PHYSICAL PROPERTIES

As with other austenitic stainless steels, 303 has good toughness and is non-magnetic. The added Sulphur makes the steel better machinable but affects the corrosion resistance and lowers the toughness of the steel slightly.

Apart from better machining the added Sulphur helps break chips into smaller, more manageable pieces, contributes to a smoother and more consistent finish and can extend tool life.

Sulphur makes this steel grade vulnerable to pitting corrosion, therefore should be avoided for environments over 140°F (60°C) containing chloride.

This steel grade is better suited in mild environments, when exposed to moist environments, like a marine environment, pitting as well as a film of rust will form. For more corrosion resistance it is better to use a steel with more chromium and nickel content.

By cold working this material grade though the crystal structure can be altered to become partially or fully magnetic. By annealing the material the process is reversed and the material goes back to its non-magnetic state.

Uniformly heat the material to 2100 - 2300°F (1149 - 1260°C) for hot working, when finished, rapidly cool the work piece to ensure the maximum corrosion resistance.

303 cannot readily be cold worked, some cold work is possible but sharp bending should not be applied.

303 TECHNICAL PROPERTIES

Typically the density of stainless steel 303 is 0.285 lb/in3 (7.9g/cm3) at room temperature.

This value is the result from a tensile test to show how much force is needed before the material starts to stretch or elongate before it breaks.

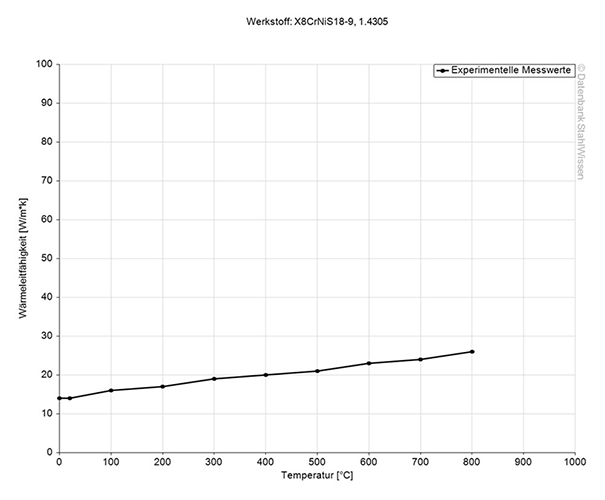

The thermal conductivity for stainless steel 303 is at 15 W/(m*K) (104 BTU/(h-ft*°F)) at room temperature.

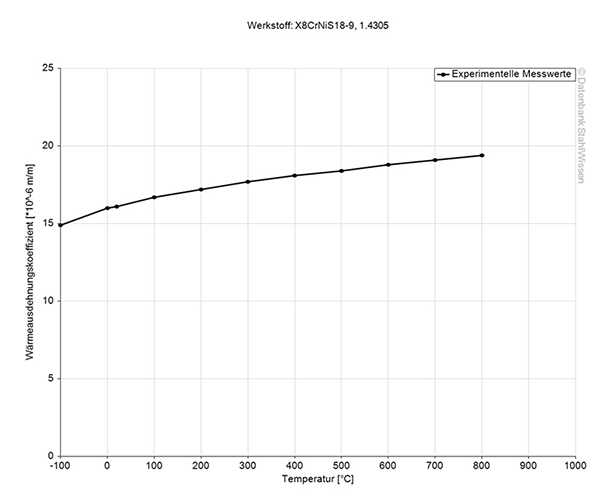

Medium thermal expansion coefficient | |

10-6m/(m • K) | At a temperature of |

16 | 68 - 212°F |

16.5 | 68 - 392°F |

17 | 68 - 572°F |

17.5 | 68 - 752°F |

18 | 68 - 932°F |

18.5 | 68 - 1112°F |

18.5 | 68 - 1292°F |

19 | 68 - 1472°F |

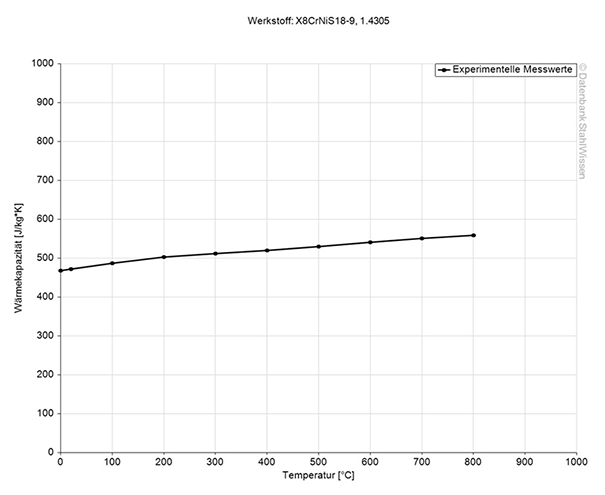

The specific heat capacity of stainless steel 303 at room temperature is ~ 0.5 J/(g*K). This value shows how much heat is needed to heat 1lb of material by 1 Fahrenheit.

Table of the specific electrical resistivity | |

Value | At a temperature of |

~0.73 (Ohm*mm²)/m | 20°C |

BECOME EVEN BETTER WITH ABRAMS PREMIUM STEEL® THAN YOUR COMPETITORS SUSPECT!

303 PROCEDURE

To prevent embrittlement and loss of corrosion resistance, temperatures between 800 - 1500°F (427 - 816°C) should be avoided for prolonged exposure.

This steel grade can be cold work hardened for improved strength and hardness. By cold working this material the crystal structure is deformed resulting in increased hardness.

303 SURFACE TREATMENT

It enhances the wear resistance and provides thermal insulation which is an advantage in high temperature and abrasive environments.

The color sequence is bronze, blue, black, charcoal, gold, purple and green. As this is a chemically induced coloring it does not flake or peel when the material is formed or drawn for example.

The oxide layer is harder which makes it better pitting resistant and does repel water and dirt.

303 PROCESSING

On a scale where 1 is weak and 6 is good, the machinability of 303 reaches a score of 6.

To avoid excess work hardening keep the cutting edges sharp. Lubricants and coolants should be used liberally to avoid the heat concentration at the cutting edges. Chip breakers should be employed to keep the workpiece clear.

With the right choice of electrodes, dielectric fluid and machining parameters the 303 stainless steel can be EDM’d which makes machining complex and intricate shapes with tight tolerances achievable.

As a non contact machining process EDM generates little heat, another advantage for the 303 as it means that the properties of this grade will not be affected.

When under constant load at higher temperatures the 303 can experience creep, a slow and time dependent deformation.

Forging is usually performed at a temperature range of 2102 - 1742°F (1150 - 950°C) with subsequent cooling in air. To minimize the risk of hot cracking, low forging temperatures are preferred.

A post forging heat treatment can be done to restore properties, reduce internal stresses and to restore the corrosion resistance for the 303.

It is not recommended to weld this steel grade.

To avoid cross contamination while fabricating, only tools dedicated to stainless steel materials should be used to avoid surface discoloration of the fabricated products.

Clean all tooling and work surfaces thoroughly against cross contamination as well.

303 APPLICATION OPTIONS

Due to its good machinability this steel grade is used for applications that require parts to be easily machined: shafts, springs bushings, nuts and bolts, valves, components in the automotive industry as well as in the machining industry.

• Food industry

• Photographic industry

• Paint industry

• Oil industry

• Soap industry

• Paper industry

• Textile industry

• Mechanical engineering

• Turned parts

• Fittings construction

• Kitchen equipment

• Decoration

303 CONCLUSION

- Austenitic chromium-nickel steel

- Free-cutting steel

- Corrosion resistant

- Non-magnetic

- Very good machinability

- Limited polishability

- Poor forgeability

- Poor weldability

- Limited acid resistance

We offer this steel as 303 Flat Stock and 303 Cold Finished Round Bars.

303 ALTERNATIVES

Are you looking for an alternative steel grade?

WE HAVE THE SOLUTION!

With the ABRAMS STEEL GUIDE, you can obtain an alternative or equivalent steel grade with just a few clicks.

303 DATASHEET

Download the technical data sheet in PDF format here.

The data shown here has been compiled with the greatest diligence and is regularly updated with regard to the correctness and completeness of its content. The content is indicative only and should not be taken as a warranty of specific properties of the product described or a warranty of suitability for a particular purpose. All information presented is given in good faith and no liability will be accepted for actions taken by third parties in reliance on this information. ABRAMS Industries reserves the right to change or amend the information given here in full or parts without prior notice.