4140 PH / 4142 PH Steel - 1.7225+QT - 42CrMo4 - Chrome-Moly

4140 PH / 4142 PH Steel - 1.7225+QT - 42CrMo4 - Chrome-Moly

Back to Steel Overview

4140 PH / 4142 PH STEEL PRICE CHART

4140 PH / 4142 PH STANDARD VALUES

C

Si

Mn

P

S

Cr

Mo

42CrMo4

27 HRC (delivery condition) - 48 HRC

max. 380 HB

42CrMo4

27 HRC (delivery condition) - 48 HRC

max. 380 HB

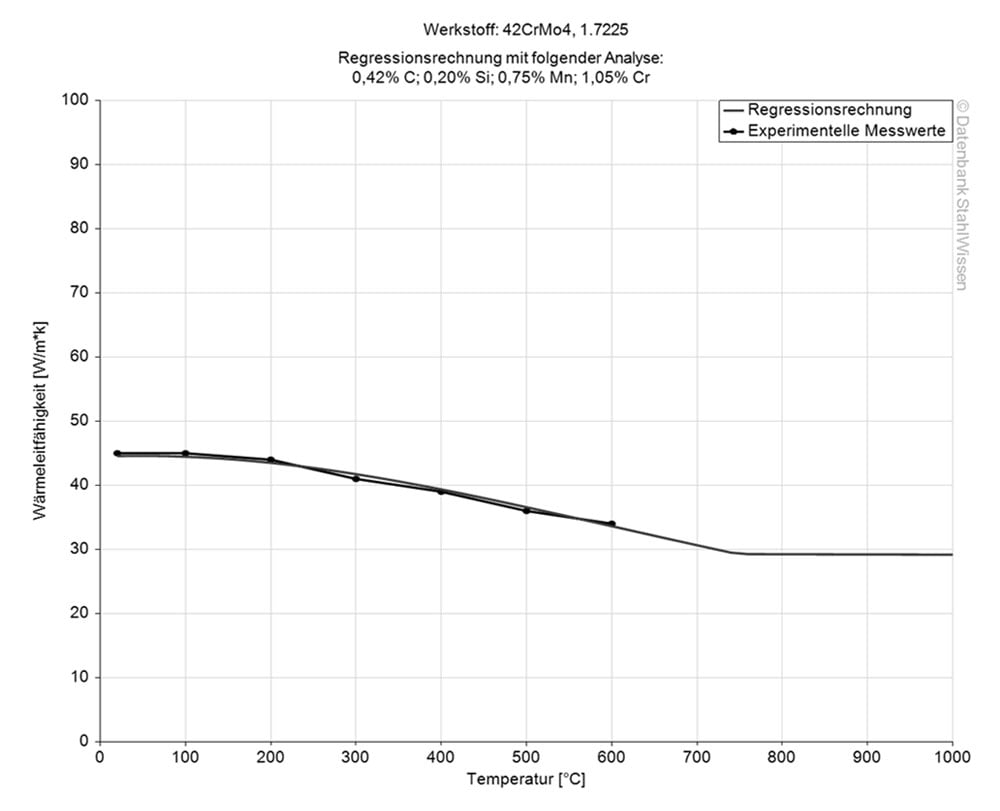

4140 PH / 4142 PH PHYSICAL PROPERTIES

As a low alloy steel, 4140 PH / 4142 PH also known as chromium-molybdenum - or chrome moly steel, it relies on the added chromium, molybdenum and manganese to increase strength and hardenability, yet it has inadequate weldability characteristics.

The chromium content in this heat-treatable steel provides hardness penetration, whereas the added molybdenum provides uniform hardness and strength. The added manganese lends itself to increase strength and hardenability.

4140 PH / 4142 PH steel may be used for both low and high temperature applications and with the relevant heat treatment can be used in sour gas environments as well. 4140 PH / 4142 PH belongs to the group of high grade structural steels.

In the quenched and tempered (PH) condition, it provides good wear resistance and has a minimum of 27 HRC which may be increased by flame or induction hardening or alternatively may as well be nitrided. In this condition, it is ready to use but still machinable as well.

4140 PH and 4142 PH are nearly identical but for a slightly higher carbon content for the 4142 PH.

Where the steel composition of the 4140 PH has a carbon content of 0.38 to 0.43%, 4142 PH has carbon content of 0.4 to 0.45%.

4140 PH / 4142 PH has some corrosion resistance due to the chromium and molybdenum content but will rust when corrosion has set in and sustain the same damage as other non-corrosion resistant steels.

This steel can be hot worked at 1500 - 1900°F (816 - 1038°C), it maintains its properties even after long exposure at the high working temperatures.

In its annealed condition, this steel can be cold worked with all the conventional methods.

4140 PH / 4142 PH TECHNICAL PROPERTIES

The density of 4140 PH / 4142 PH at room temperature (~68°F) is 0.284lb/in3 (7.85g/cm3).

The heat conductivity for the 4140 PH / 4142 PH at room temperature is at 42.6 W/(m*K) (313 BTU/(h-ft2*°F)).

| Value | By temperature |

|---|---|

| 42.6 W/(m⋅K) | 68 °F |

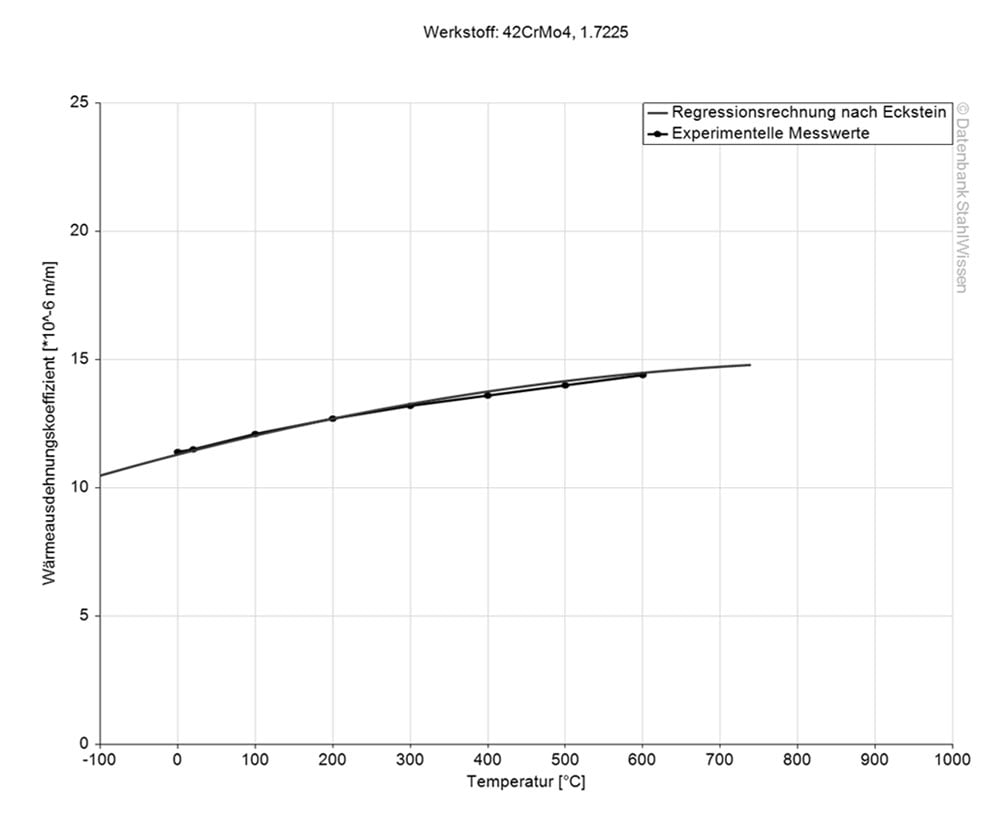

| 10-6m/(m•K) | At a temperature of |

|---|---|

| 11.1 | 68 - 212 °F |

| 12.1 | 68 - 392 °F |

| 12.9 | 68 - 572 °F |

| 13.5 | 68 - 752 °F |

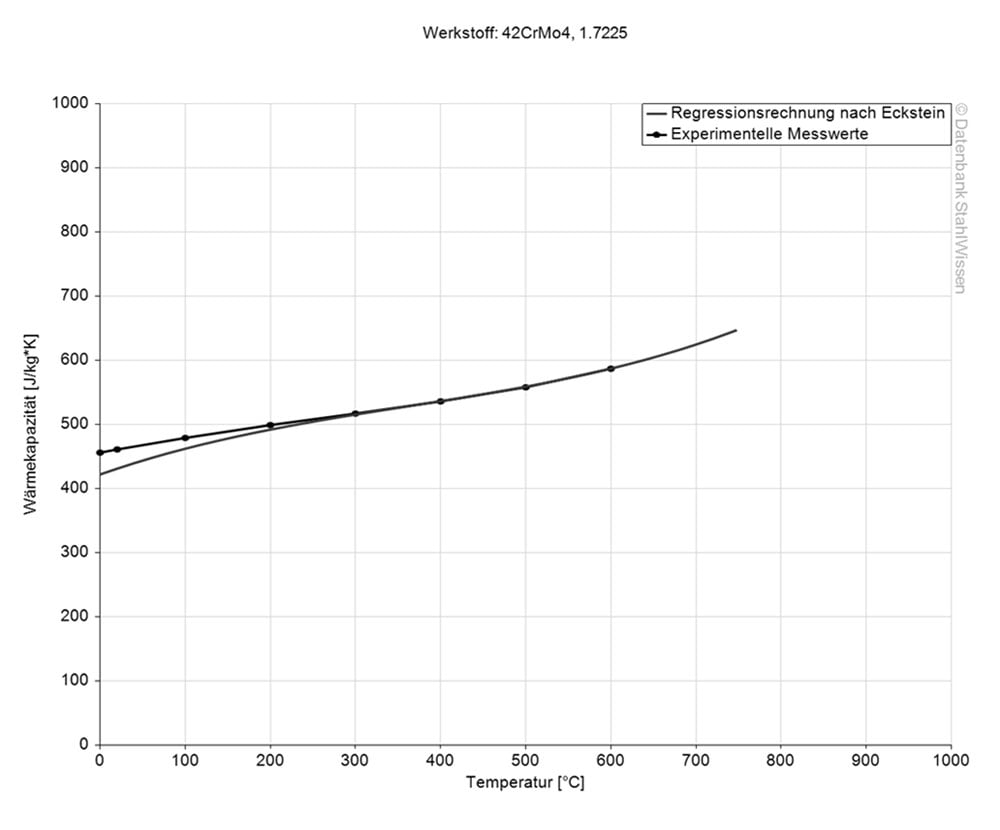

This value shows how much heat is needed to heat 1lb of 4140 PH / 4142 PH by 1 Fahrenheit.

| Value | At a temperature of |

|---|---|

| ~ 0.231 (Ohm⋅mm²)/m | ~ 68 °F |

| ~ 0.284 (Ohm⋅mm²)/m | ~ 212 °F |

| ~ 0,358 (Ohm⋅mm²)/m | ~ 392 °F |

| ~ 0,448 (Ohm⋅mm²)/m | ~ 572 °F |

| ~ 0,552 (Ohm⋅mm²)/m | ~ 752 °F |

| ~ 0,671 (Ohm*mm²)/m | ~ 932 °F |

ON REQUEST – SAWN – MILLED – GROUND!

4140 PH / 4142 PH PROCEDURE

After hardening the material can achieve a working hardness between 262 and 456 BHN (27 - 48 HRC).

4140 PH / 4142 PH can be quenched in oil to room temperature and then should be tempered immediately.

As delivered: Alloy 4140PH / 4142 PH does not require a tempering as it is pre-hardened. If this material should be re-hardened, follow the annealing and hardening process as described above.

Re-hardened: Alloy 4140 PH / 4142 PH can be tempered at 1004 - 1256°F (540 - 680°C) subject to hardness and according to the properties required. Cool in air after the treatment.

4140 PH / 4142 PH can be tempered at 1004 - 1256°F (540 - 680°C), the higher the tempering temperature the softer and more ductile it gets.

In general hardness and ductility are determined by tempering the material, the higher the ductility the lower the hardness which is true for the reverse as well. Apart from the advantage to give the steel the wanted and needed properties the material can be stress relieved, is less likely to crack and has a better deformation behavior by tempering it.

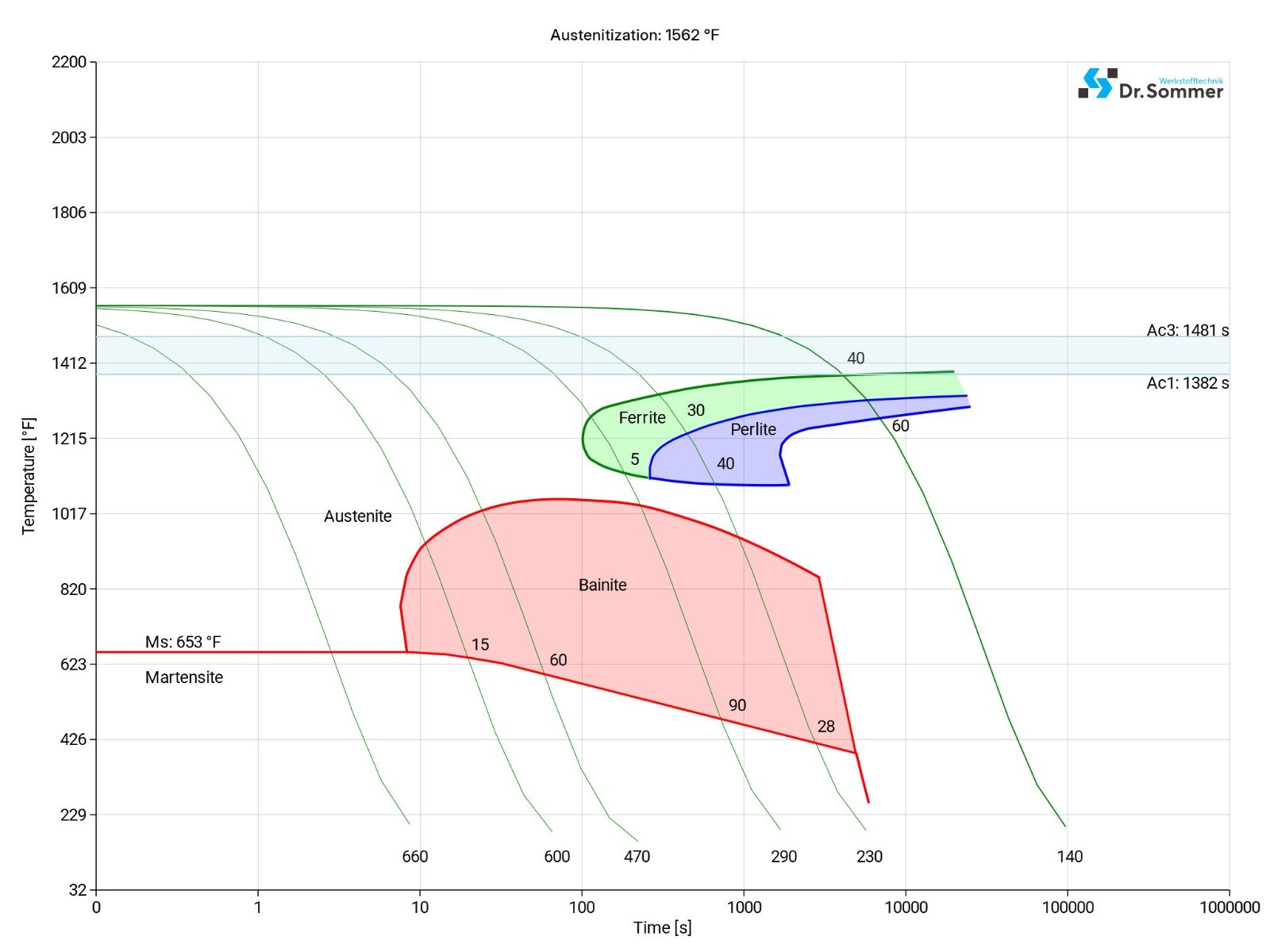

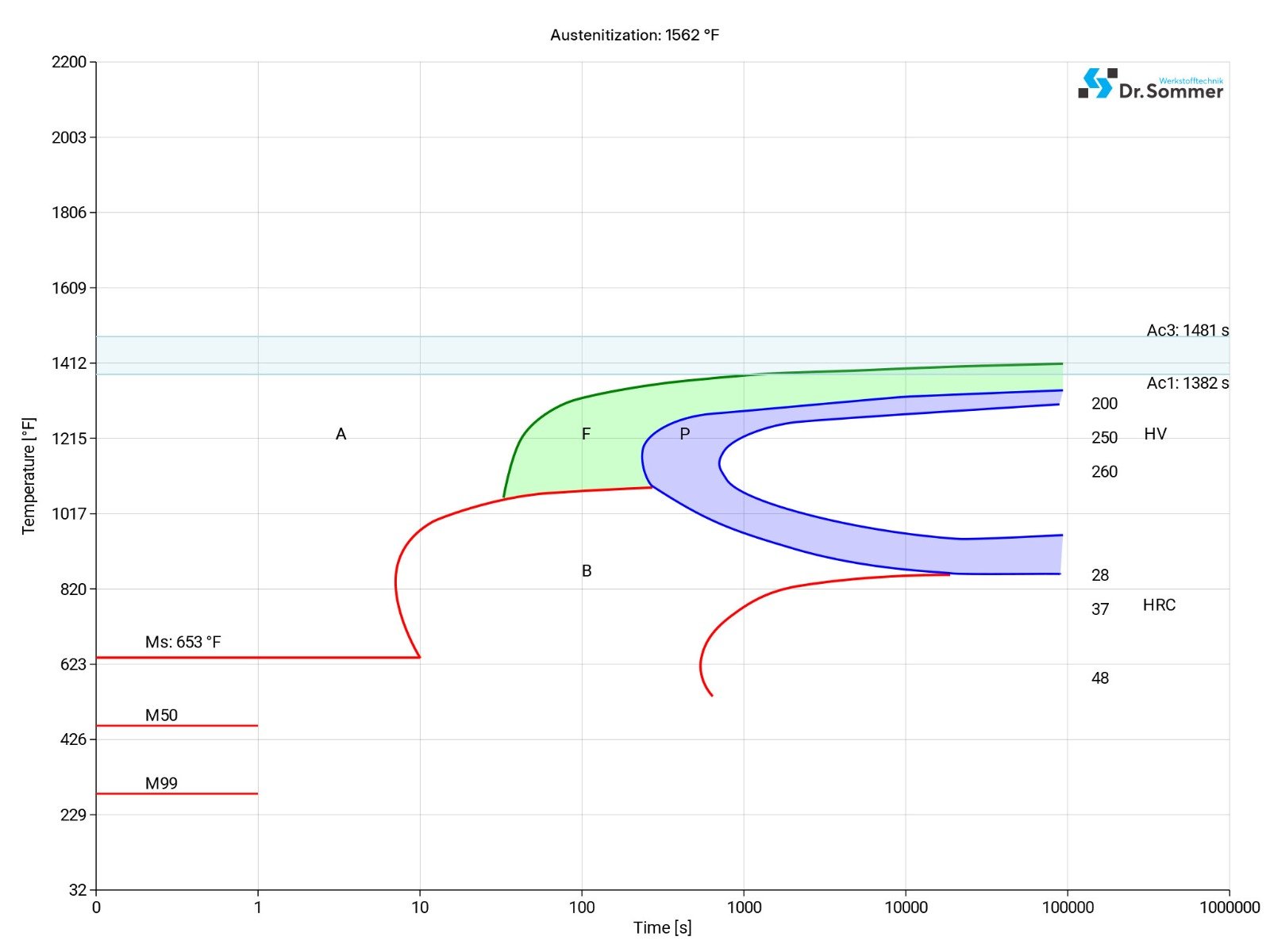

This diagram shows micro changes over time at different temperatures. Those are important during heat treatment as they show information about the optimum conditions for processes such as hardening, annealing and normalizing.

This diagram shows the structural changes at micro level over time at a constant temperature. It shows at what temperature and after what time different phases, e.g., perlite, martensite or bainite start to build.

4140 PH / 4142 PH SURFACE TREATMENT

4140 PH / 4142 PH PROCESSING

On a scale where 1 is weak and 6 is good, the machinability of 4140 PH / 4142 PH reaches a score of 3.

It is possible to EDM this steel grade in the annealed and hardened condition. As for all EDM work the recast layer has to be removed thoroughly by stoning and polishing.

Annealed or normalized: 4140 PH / 4142 PH can be forged in a temperature range of 1652 - 1832°F (900 - 1000°C) followed by a very slow cooling in still air or sand.

Welding 42CrMo4 may only be done in the annealed or normalized condition. All conventional techniques may be applied then.

Annealed or normalized: In order to prevent cracking, preheat to 350-650°F (177-350°C). Due to the level of carbon in this steel, pre- and post-heat is recommended. Cool slowly to prevent/reduce embrittlement.

If welded in the heat-treated condition, which is normally only done for repairs, mechanical properties are affected and a post-weld heat treatment should be performed. Welding pre-heated parts, it is recommended to stress relieve the parts before at a temperature 60°F (15°C) below the original tempering temperature in order to prevent cracking.

4140 PH / 4142 PH APPLICATION OPTIONS

Applications for this 4140 PH / 4142 PH flat stock steel include: arbors, flanges, collets, bending dies, crankshafts, clutch parts, forming rolls, and short run stamping dies.

• Mechanical engineering

• Machine parts

• Axes

• Knuckles

• Connecting rods

• Crankshafts

• Gear shafts

• Pinions

• Gears

• Bandages

• Base plates

• Assembling parts

4140 PH / 4142 PH CONCLUSION

- Engineering steel

- High strength

- High toughness

- Good machinability

- For highly stressed components in vehicle construction

- Surface hardenable

- Nitridable

- Erodible

- Difficult to weld

We offer this steel as 4140 PH Precision Ground Flat Stock /4142PH, 4140 PH Flat Stock / 4142 PH, 4140 PH Round Bars Decarb Free / 4142 PH and 4140 PH Drill Rods / 4142 PH - Pre-Hardened.

4140 PH / 4142 PH ALTERNATIVES

Are you looking for an alternative steel grade?

WE HAVE THE SOLUTION!

With the ABRAMS STEEL GUIDE, you can obtain an alternative or equivalent steel grade with just a few clicks.

4140 PH / 4142 PH DATASHEET

Download the technical data sheet in PDF format here.

The data shown here has been compiled with the greatest diligence and is regularly updated with regard to the correctness and completeness of its content. The content is indicative only and should not be taken as a warranty of specific properties of the product described or a warranty of suitability for a particular purpose. All information presented is given in good faith and no liability will be accepted for actions taken by third parties in reliance on this information. ABRAMS Industries reserves the right to change or amend the information given here in full or parts without prior notice.