Buy Plastic Mold Steel without any Minimum Order Value or Quantity

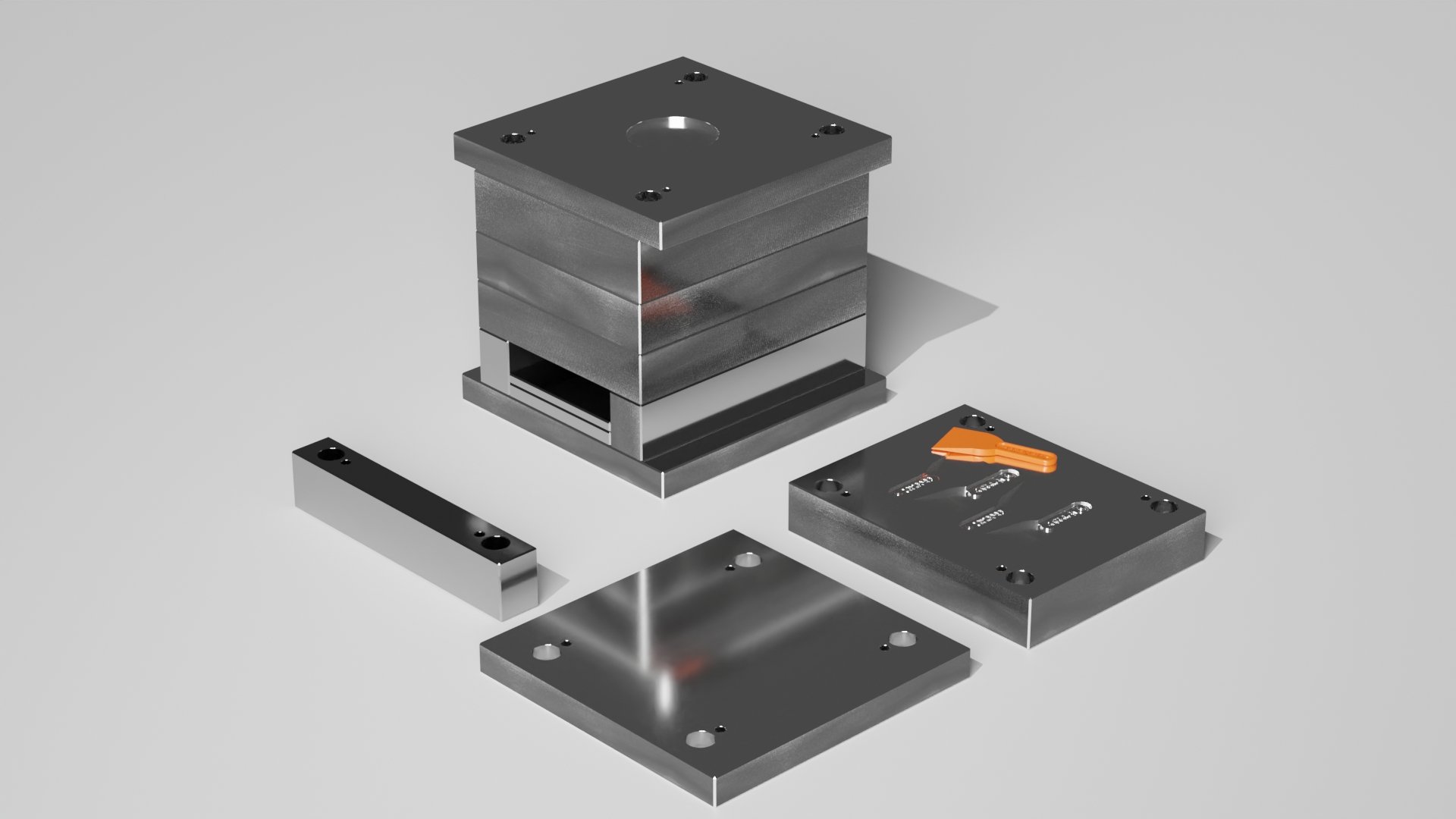

Mold steels are used in industrial production for the manufacture of molds and tools. They can be utilized for injection molding, die casting, blow molding, and other manufacturing processes.

Due to various requirements, mold steel must possess a range of important properties. This ensures that the molds produced have a long lifespan, fulfill their function and deliver high-quality end products.

Plastic mold steel is a combination of hardness, toughness, wear resistance, corrosion resistance, thermal conductivity, polishability, dimensional stability and form stability.

Your success is our success!

VARIOUS TYPES OF STEEL FOR MOLD MAKING

The success of these industries largely depends on the quality and precision of the tools and molds used. The right steel is essential in this context. To meet the specific requirements and challenges of plastic injection molding, various grades or types of steel are used.

HOW TO SELECT THE RIGHT MOLD STEEL FOR MOLDING

1. What type of casting process is being used?

2. What mechanical requirements are needed?

3. What thermal requirements are necessary?

4. What level of chemical resistance must the steel have?

5. Is machinability a critical factor?

6. What surface finish requirements are there?

7. Cost-effectiveness – How much can the steel cost?

HOW HARD IS MOLD STEEL?

Are you asking yourself how high the hardness of mould steel is? The working hardness of mold steel ranges from 277 to 711 BHN. Each type of steel has different properties and a specific hardness. The individual values are listed in the table.

Molding steel | Range of Hardness (Brinell Hardness Number) |

AISI / SAE A2 | 601 - 658 BHN |

AISI / SAE D2 | 592 – 658 BHN |

AISI / SAE H10 | 469 - 504 BHN |

AISI / SAE H13 | 469 - 572 BHN |

AISI / SAE H13 ESR | 469 - 572 BHN |

AISI / SAE O1 | 592 - 658 BHN |

AISI / SAE P20 | 300 - 469 BHN |

AISI / SAE P20 PH | 300 - 469 BHN |

AISI / SAE P20 + Ni | 300 - 469 BHN (delivery condition, quenched and tempered) |

AISI / SAE S7 | 572 - 627 BHN |

AISI / SAE Toolox 33 | 277 - 331 BHN (on delivery, without nitriding) |

AISI / SAE Toolox 44 | 419 BHN (on delivery) |

AISI / SAE 2990 mod. | 592 - 681 BHN |

AISI / SAE 420 ESR | 469 - 552 BHN |

AISI / SAE 420 LC | approx. 308 BHN (on delivery) |

AISI / SAE 420 FM | approx. 308 - 456 BHN (on delivery) |

AISI / SAE 5120 | 601 - 627 BHN |

AISI / SAE 6F7 ESR | 469 - 534 BHN |

AISI / SAE M2 | 658 - 711 BHN |

AISI / SAE M4 | 658 - 711 BHN |

AISI / SAE 420 | 469 - 552 BHN |

AISI / SAE 420 RM | 277 - 456 BHN |

AISI / SAE 440B | approx. 513 - 601 BHN |

AISI / SAE 5115 | 601 - 627 BHN (on the surface) |

SUMMARY

Mold steel is the generic term for steels which, due to their properties, are used for plastics processing and machining as well as for cold or hot working applications.

Mold steels have to fulfill a great variety of properties. Therefore they can be found amongst tool steel, high speed steel, stainless resistant steel as well as case hardening steel.

The properties below are an overview of properties mold steels should have to guarantee a perfectly finished end product.

• Dimensional stability

• Corrosion resistant

• High wear resistant

• High thermal conductivity

• High polishable

• Good toughness

• Long service life

• Shock resistant

• Impact resistant