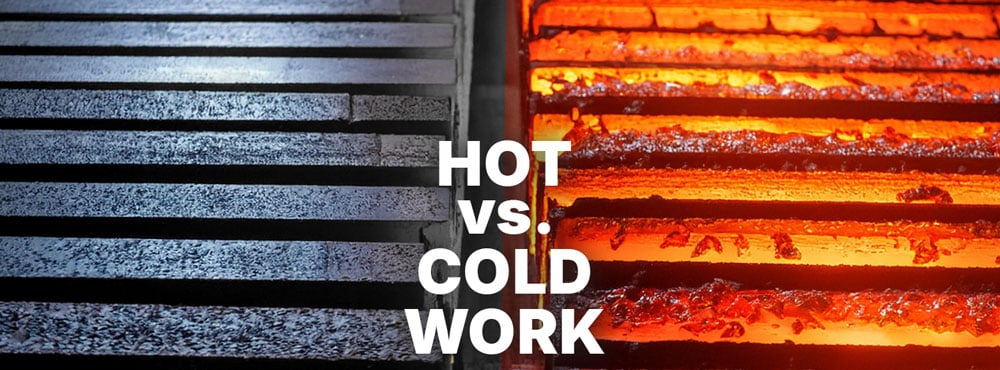

Hot work vs Cold work - The Differences in the Steel processing

In steel processing, the question often arises as to whether hot-work or cold-work steel should be used.

When choosing hot work vs cold work steel, it is important to understand the unique and common properties to ensure the best performance and tool life, with the final application playing a big factor when choosing too.

ABRAMS INDUSTRIES® INC.

YOUR STEEL PARTNER

We saw, mill and grind for you in our Warehouse in Illinois.

As a steel supplier with no minimum order quantity or value we have been supplying steel to a wide variety of industries and manufacturers in Germany since 2003, Europe since 2011 and since 2020 across the U.S.A. and Canada.

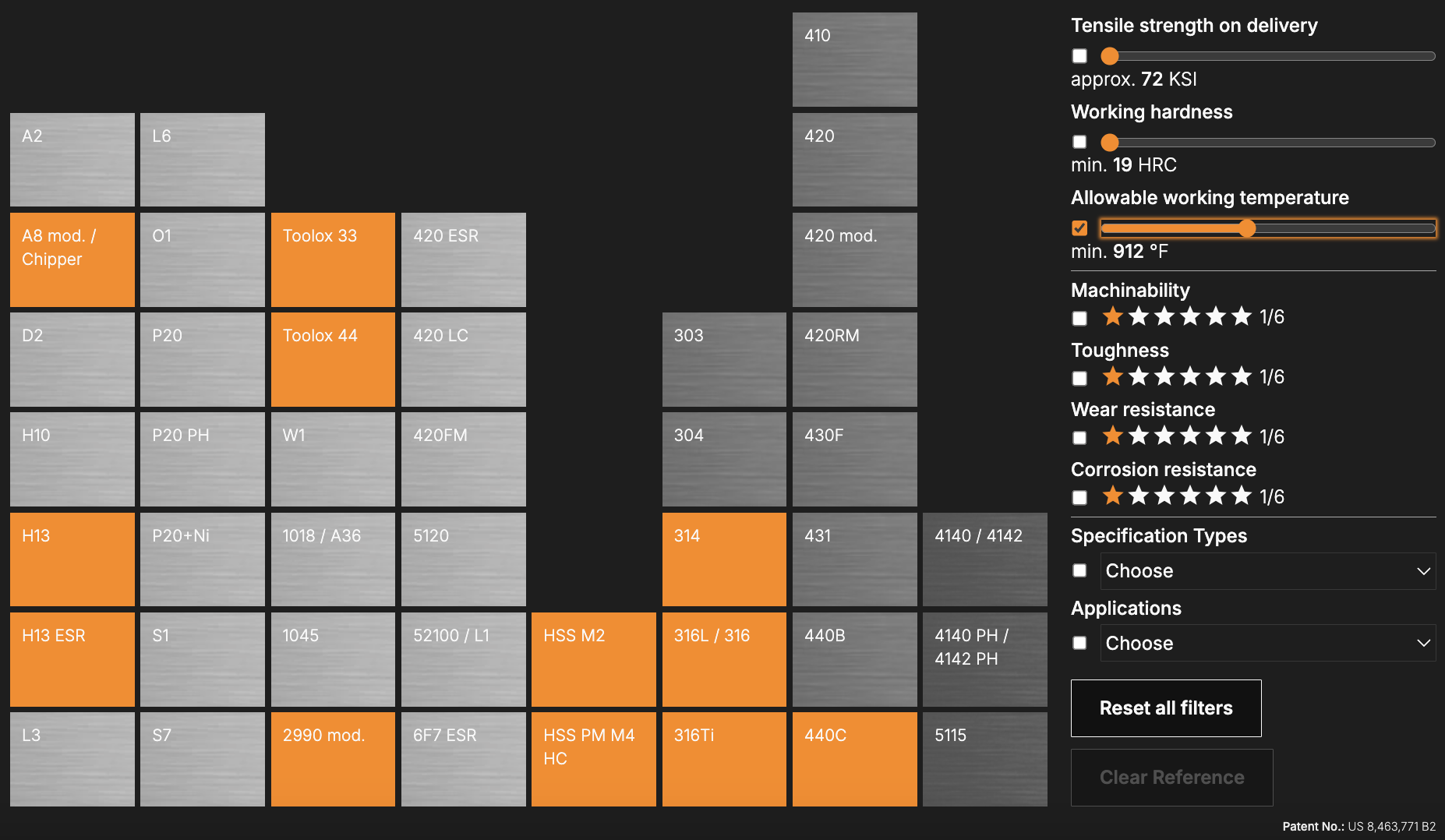

We pride ourselves in supplying you with precision in steel in 44 steel grades with 83,928 dimensions.

ABRAMS INDUSTRIES® INC.

YOUR STEEL PARTNER

We saw, mill and grind for you in our Warehouse in Illinois.

As a steel supplier with no minimum order quantity or value we have been supplying steel to a wide variety of industries and manufacturers in Germany since 2003, Europe since 2011 and since 2020 across the U.S.A. and Canada.

We pride ourselves in supplying you with precision in steel in 44 steel grades with more than 53,000 dimensions.

STEEL PROPERTIES OF COLD WORK VS. HOT WORK

There are large and small but subtle differences between cold and hot work steels. The main property differences are listed in the table below.

Property | Cold work | Hot work |

Temperature | At or around room temperature - under the recrystallization temperature | Above the recrystallization temperature |

Alloying element C | The alloying carbon content for cold work steel is high to guarantee hardness and wear resistance. | The carbon content for hot work steel is low with its focus on red hardness, thermal conductivity and wear resistance. |

Surface finish | Smooth finish allowing high precision and dimensional accuracy. No machining needed | Rougher finish due to oxidation and scaling, less precision and descaling might be needed. |

Mechanical properties | 1. Increased hardness and strength through strain hardening. 2. Reduced ductility 3. Internal stresses | 1. No strain hardening 2. Enhanced ductility and toughness 3. Less internal stresses (no strain hardening) |

Deformation | Force is needed due to the low temperature. The material is left harder and less malleable. | Due to the heated state of the material it is easier to form and is more malleable. |

Grain structure | Can lead to a distorted grain structure, which in turn can lead to uneven mechanical properties. | Produces a uniform and refined grain structure, which has a positive effect on consistent mechanical properties. |

Requirements for post-processing | Due to internal stresses and reduced ductility an additional annealing might be needed. | A post annealing process is not needed as there are no internal stresses. For special applications a post heat treatment might be applied. |

What applications can cold or hot work steel be used for?

Cold work steel: Due to the force needed to deform this type of steel it is only used for smaller sized parts and pieces like precision fasteners, precision tools or surgical tools. | Hot work steel: This steel is used for large shapes that can be significantly deformed to produce beams, rails, pipes and structural elements. Due to the used heat, deformation is done easier and can be used for large components. |

Automotive: Fasteners, body panels

Construction: Steel studs, rebar ties

Pipes and tubes: Thin walled precision tubes, medical devices

Tools and dies: Small molds and dies, high precision tools

Aerospace: Skin panels, brackets

Electrical: Connectors, terminals

Shipbuilding: Fasteners, fittings

Automotive: Chassis parts, crankshafts

Construction: I-beams, H-beams

Pipes and tubes: Thick walled and seamless tubes, boilers

Tools and dies: Large molds and dies, forging tools

Aerospace: Turbine blades, structural components

Electrical: Transformers, structural components

Shipbuilding: Hull plates, bulkheads

HOW TO CHOOSE BETWEEN COLD WORK AND HOT WORK STEEL

When choosing hot work or cold work steel several factors should be taken in consideration.

What properties does the final product need?

What manufacturing processes will be used?

What applications will the parts be used for?

How small or big do the parts have to be?

Cold work steel is chosen when increased strength, hardness, dimensional accuracy, tight tolerances, and a smooth finish as well as a high consistency and repeatability is needed for the production of intricate and complex shapes with high precision.

Hot work steel is used when surface finish and precision are secondary to ductility, toughness, a refined grain structure and the easiness of shaping large components.

Advantages and disadvantages of cold work and hot work steel

This is an overview of the advantages and disadvantages that should be taken in consideration when choosing between hot work and cold work steel.

Advantages for cold work steel: Increased strength Increase hardness High dimensional accuracy Smooth surface finish No heat needed | Advantages for hot work steel: Very high ductility Very good toughness Minimized internal stresses Production of large components |

Disadvantages for cold work steel: Reduced ductility Internal stresses Limited deformation High force is required | Disadvantages for hot work steel: Low dimensional precision Rough / scaly surface High energy costs Oxidation may be possible |

SUMMARY

So the question is still hot work or cold work steel? Which properties are important to you? Strength and hardness, then you should choose cold steel. Or ductility and toughness, then you should choose hot work steel.

• You have working temperatures over 392 °F - then you need hot work steel

• You have working temperatures under 392 °F - your answer is cold work steel

Understanding which requirements the steel has to fulfill is understanding which of the two you need to manufacture parts and tools or for which application you can use either one.

Dr. Jürgen Abrams

Founder, CEO

Experienced steel specialist

Dr. Jürgen Abrams is the founder and CEO of ABRAMS Industries®, a customer-oriented company specializing in premium steel and customized precision steel and aluminum.